This grid-connected wind-solar hybrid power generation system, with a power generation capacity of 20 to 50 kW, is specifically designed for villages, small and medium-sized communities, farms, estates, enterprises and other scenarios with public grid coverage. It takes "wind energy + solar energy" dual-source power generation as its core, focuses on the grid-connected power generation without energy storage, eliminates the energy storage link, and enables efficient access to the public grid. It also takes into account "self-consumption + surplus power income". With convenient installation, easy operation and APP intelligent control, it makes clean power generation more worry-free and practical.

Core Configuration

The core components of the system are precisely matched, with parameters strictly adhering to grid connection requirements. From power generation to grid connection, the entire process is stably connected to ensure efficient output of clean power:

Dual-source power generation core: Equipped with high-efficiency wind power generation units and high-conversion-rate photovoltaic modules, it utilizes the natural complementarity of wind and solar energy to provide a continuous and stable power input for grid connection, balancing short-term energy fluctuations without relying on energy storage devices and ensuring a stable power supply for grid connection.

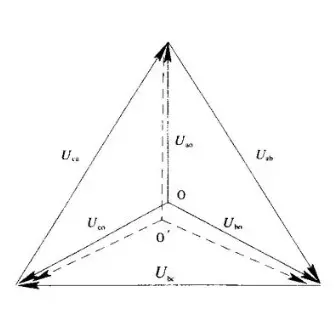

Standard voltage output: The inverter is precisely matched with the grid, with a rated output of three-phase AC 400V 50/60Hz standard voltage, fully meeting the requirements for grid connection. No additional voltage regulation equipment is needed, and direct grid connection can be achieved.

Multiple power coverage: The system's rated power covers different levels, meeting the daily power needs of 3-5 households and the surplus power grid connection requirements, as well as supporting the power needs of 10 or more households or small agricultural machinery (such as water pumps and irrigation equipment), adapting to various grid connection scenarios. Main features

Features

1. Grid-connected power generation without energy storage: Simplified structure, cost reduction and maintenance reduction

More convenient direct connection to the grid: Eliminating components such as energy storage batteries, the inverter output directly matches the grid standards, eliminating the need for additional adaptation processes, allowing for quick access to the public grid and simplifying the system structure;

Lower cost and more economical: Reducing the procurement and installation costs of energy storage equipment, the overall investment threshold is lower, better fitting the budget of rural users;

Significantly reduced maintenance burden: No need for regular charging and discharging maintenance or replacement of energy storage batteries, avoiding issues such as battery aging and performance decline at low temperatures, reducing the difficulty and cost of later operation and maintenance, suitable for scenarios lacking professional maintenance personnel.

2. Easy installation: Modular pre-testing, no difficulty in operation

Modular component design: Core components such as wind power generation units, photovoltaic modules, and inverters are all pre-tested modules, with parameters already matched in advance. No need for re-testing on site, and they can be assembled directly upon opening the box;

Simple fixation saves time: Photovoltaic modules are paired with snap-on brackets, eliminating the need for drilling and pouring, and can be quickly assembled by two people. The base of the wind power generation unit can be directly fixed to a cement floor or open space, only requiring simple fixation of anchor bolts, without the need for complex foundation construction;

Clear wiring without confusion: The controller has "foolproof interfaces" reserved, clearly marked with ports such as "wind power input, photovoltaic input, grid connection, and load output". By following the manual, wiring can be completed easily, and ordinary users can operate it without the need for a professional construction team.

3.Convenient operation: Intelligent adaptation, no need for professional skills

Automatic working condition adaptation: MPPT technology can automatically adjust the working state of the power generation equipment through voltage tracking, eliminating the need for manual adjustment, ensuring maximum power generation efficiency;

Automated grid connection process: When the power generation exceeds the self-use demand, the excess power is automatically sent to the grid; when the power generation is insufficient, it automatically switches to drawing power from the grid, eliminating the need for manual intervention throughout the process, achieving stable power supply of "self-use + grid backup";

Automatic fault protection: When the system encounters abnormalities (such as voltage fluctuations, component connection issues), it will report an error and shut down the related power generation equipment, automatically protecting the lines and equipment.

4.Supports APP operation: Remote control, full visibility of power generation status

Real-time data monitoring: Open the APP to view the total power generation, self-consumption, and surplus power sent to the grid, clearly understanding the entire process of "power generation - consumption - grid connection", and intuitively calculating the grid connection income;

Grid connection status control: Real-time monitoring of the grid connection status. If there is an abnormality in the grid connection (such as line disconnection, voltage mismatch), an immediate warning message will be pushed to avoid income loss;

Remote mode switching: Supports one-click switching between "self-use priority" and "grid connection priority" modes. For example, during off-peak electricity usage, prioritize sending power to the grid, and during peak usage, prioritize meeting self-use needs, flexibly adapting to different time period demands.

Application scenarios

Rural household scenarios: Meeting the daily electricity needs of household lighting, refrigerators, washing machines, rice cookers, etc. Surplus power sent to the grid can subsidize electricity expenses, reducing living costs;

Agricultural production scenarios: Providing power for water pumps, small-scale agricultural machinery for irrigation, and power supply equipment for seedling greenhouses. Excess power can be sent to the grid, ensuring agricultural production while increasing additional income for farmers;

Rural public facility scenarios: Supplying power to rural street lamps, cultural activity rooms, health clinics, etc. Surplus power sent to the grid can offset public electricity expenses, reducing the financial pressure on the village.

Generate power and earn income.

Parameters

product number |

WPHBT360-20 |

WPHBT360-30 |

WPHBT360-50 |

Wind Turbine |

Model |

FD10-20K |

FD10-30K |

FD10-20K |

Configuration |

1S1P |

1S1P |

1S2P |

Rated output Voltage |

360V |

360V |

360V |

Photovoltaic |

Model |

SP-600-V |

SP-600-V |

SP-600-V |

Configuration |

7S2P |

7S3P |

20S2P |

Rated output Voltage |

254V |

254V |

720 V |

Wind Turbine inverter |

Model |

WWGIT200 |

WWGIT300 |

WWS500 |

Rated input Voltage |

360V |

360V |

360V |

Rated output Voltage |

400VAC |

400VAC |

400VAC |

Configuration |

1S1P |

1S1P |

1S1P |

Inverter |

Model |

GW8K-STD-30 |

GW12K-STD-30 |

GW25K-STD-30 |

Input Voltage range |

140-1000V |

140-1000V |

140-1000V |

Rated Power |

8kW |

12kW |

25kW |

Rated output Voltage |

Three-phaseAC400V 50/60Hz |

Three-phaseAC400V 50/60Hz |

Three-phaseAC400V 50/60Hz |

Configuration |

1S1P |

1S1P |

1S1P |