(I) Problem Background

Ensuring the long-term safe, stable, and efficient operation of electrical cable systems is crucial for guaranteeing the continuity of production, daily life, and facility operations. Proper selection is the cornerstone of system reliability, while consistent and effective maintenance management is the core safeguard against faults, extending cable lifespan, and preventing economic losses and safety incidents. Neglecting selection principles or insufficient maintenance management can easily lead to cable overload, overheating, accelerated insulation aging, short circuits, and even fire risks.

(II) Solution

2.1 Scientific Selection Principles

Cable selection is not simply based on load requirements but requires comprehensive multi-dimensional and forward-looking consideration. The core principles are as follows:

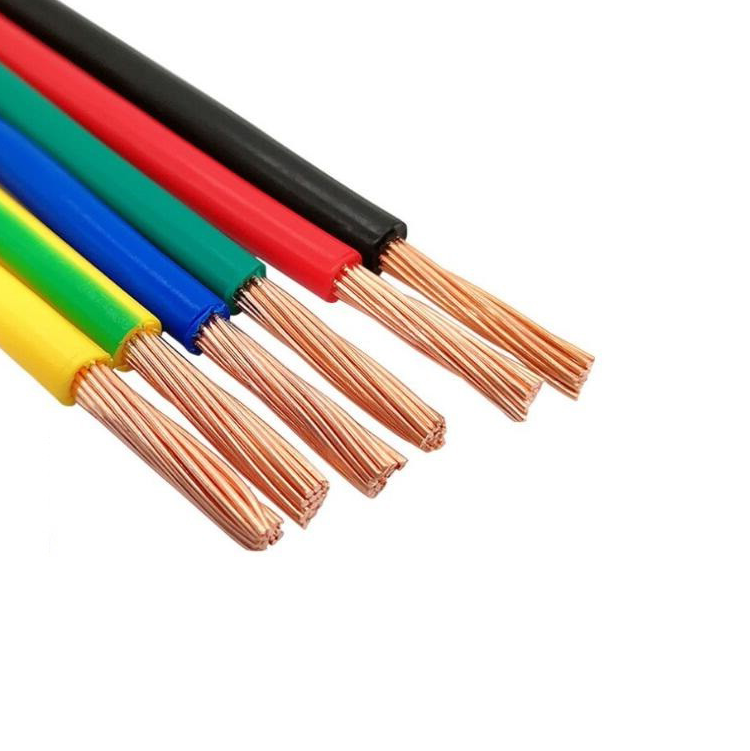

- Load Current Matching: The primary consideration is the continuous operating load current value. Line current must be accurately calculated based on factors including equipment power consumption, starting current (considering starting frequency and duration), and the system's design maximum current. The rated current-carrying capacity of the selected cable must be greater than or equal to this calculated current value, and the appropriate conductor cross-sectional area must be chosen according to relevant national/industry standards (e.g., GB/T 12706, IEC 60502, etc.). Overload operation is strictly prohibited.

- Ambient Temperature Correction: Ambient temperature significantly impacts cable ampacity.

- High-Temperature Environments: Such as hot workshops, tropical regions, areas with concentrated cable trays/ladder racks, or near heat sources. The rated ampacity must be derated using the appropriate correction factor (usually less than 1) for that temperature. Priority should be given to cables with high-temperature-resistant insulation materials (e.g., cross-linked polyethylene (XLPE) is more heat-resistant than PVC) or cables rated for higher temperatures.

- Low-Temperature Environments: Low temperatures may cause material embrittlement, affecting installation and bending performance. The cable's low-temperature resistance grade must be considered during selection.

- Installation Method and Heat Dissipation Conditions:

- Distinguish between installation in air (exposed, trays/ladder racks, conduits), direct burial in soil, conduit installation, or bundled installation.

- Different installation methods have vastly different heat dissipation capabilities, directly impacting ampacity. For example, soil thermal resistivity and burial depth must be considered for buried cables; dense bundling significantly reduces ampacity and requires consulting ampacity tables for the specific installation method or applying derating factors. Prioritize methods conducive to heat dissipation or allow larger margins.

- Voltage Level Matching: The cable's rated voltage (e.g., 0.6/1kV, 8.7/15kV, etc.) must be greater than or equal to the system's operating voltage plus any possible transient overvoltages to ensure sufficient insulation strength.

- Insulation Type and Sheath Material:

- Insulation Material: Selected based on temperature rating, mechanical strength, dielectric properties, and flame retardancy (e.g., Low Smoke Zero Halogen - LSZH).

- Sheath Material: Must suit environmental demands:

- General Environment: PVC, PE, etc.

- High Mechanical Protection Requirement: Armored cables (steel tape, steel wire armor).

- Corrosion Resistance (e.g., chemical plants, salt spray areas): Non-magnetic metal armor (e.g., aluminum alloy tape) or special anti-corrosion sheaths.

- Flame Retardant/Fire Resistant: Select flame-retardant cables of appropriate levels (ZA, ZB, ZC, etc.) or fire-resistant cables (e.g., Mineral Insulated - MI).

- UV Resistance: For outdoor use or direct sunlight exposure, materials resistant to UV (e.g., black weather-resistant PVC/PE) are essential.

- Short-Circuit Current Requirements: The cable must withstand the thermal effects generated by the system's maximum possible short-circuit current for its duration without damage. Calculation of the short-circuit thermal withstand current is required to select a cable with sufficient cross-section or to implement other protective measures.

2.2 Systematic Maintenance Management Methods

Regular, targeted maintenance inspections are key to identifying hidden risks early and preventing escalation. Main methods include:

- Periodic Infrared Thermographic Inspection (Cyclic Patrols):

- Core Objective: Non-contact accurate detection of abnormal temperature rises at critical connection points like joints, terminations, connectors, and cable ends.

- Frequency: Recommended quarterly to semi-annually for critical areas and heavily loaded lines; at least annually for general areas; increase frequency before/after major events or during peak temperature seasons.

- Advantage: Early detection of hidden faults like poor connections, overloads, phase imbalance, etc., preventing fire hazards.

- Environmental Suitability Check:

- Humid/Corrosive Environments: Focus on inspecting the integrity of the cable outer sheath (especially at joints) for damage, aging, or cracking. Inspect termination sealing and junction box waterproofing. Use specialized sealants or waterproof joints if necessary.

- Mechanical Damage Risk Areas: Inspect cable outer sheath for scratches, crushing, or pressure from sharp objects; check the stability of trays/ladder racks and supports; inspect for signs of unauthorized excavation or heavy machinery over buried sections.

- Insulation Performance Monitoring and Diagnostics (Preventive Testing):

- Regular Insulation Resistance Testing: Use a megger to measure insulation resistance between phases and to ground to identify significant deterioration or moisture ingress.

- Dielectric Loss Factor (Tanδ) or Partial Discharge Testing (for MV/HV Cables): More advanced diagnostic tools to assess insulation aging and potential defects. Conduct per scheduled intervals mandated by regulations.

- Lifecycle Management and Replacement Strategy:

- Recording and Analysis: Maintain detailed cable records (model, length, installation date, location, historical test data, repair history).

- Assessing Aging State: Evaluate the overall cable aging status considering service life, load history, environmental conditions, and historical test data (insulation resistance, Tanδ, partial discharge, etc.).

- Preventive Replacement: Develop planned replacement strategies for important circuit cables nearing design life or assessed to be in poor aging condition, avoiding passive failures causing greater losses.

- Storage and Spare Management:

- Storage Conditions: Spare cables should be stored indoors in cool, dry, and well-ventilated warehouses.

- Avoid Direct Sunlight: Prolonged exposure to sunlight must be strictly prohibited to prevent UV degradation causing sheath and insulation aging, cracking, or embrittlement (especially significant for PVC). Outdoor temporary storage requires covering with a light-blocking tarp.

- Proper Storage: Avoid haphazard stacking, heavy loads, or tight-radius bends to prevent mechanical damage and deformation. Ensure cable ends remain well-sealed.

(III) Key Implementation Points

- Develop Detailed Procedures: Formalize the above selection principles and maintenance methods into this project's "Cable Selection Technical Specifications" and "Cable System Maintenance Procedures".

- Personnel Training: Ensure engineers, procurement personnel, and maintenance electricians understand and strictly adhere to selection principles and maintenance methods, particularly temperature correction factors, IR scan interpretation, and sealing inspection requirements.

- Establish Records: Maintain complete archives for each critical cable route, tracking selection basis, installation records, test data, and maintenance logs.

- Provide Tools: Equip maintenance personnel with necessary tools and instruments (e.g., IR camera, megger, logbooks).

- Closed-Loop Management: Promptly report, assess, and repair issues found during inspections; document and analyze root causes, continuously improving management measures.

(IV) Expected Outcomes

Through strict adherence to scientific selection principles and the implementation of systematic maintenance management:

- Significantly enhance system reliability: Minimize cable failures caused by improper selection or poor maintenance.

- Extend service life: Slow down insulation aging, fully realizing the design life potential of cables.

- Safeguard personnel and property safety: Effectively prevent electrical shock and fire risks caused by cable overheating, short circuits, etc.

- Optimize operating costs: Reduce costs associated with emergency repairs, production downtime, and expensive cable replacements.

- Comply with regulations and standards: Meet relevant national and industry safety regulations for electrical equipment operation management.

This plan combines meticulous front-end selection with comprehensive lifecycle management throughout the back-end, establishing a continuous security assurance system for electrical cables.