- What is a Pole-Mounted Switch?

A mechanical switching device installed on outdoor utility poles in 10kV overhead distribution lines, used in suburban and rural distribution networks. It is designed to break, close, and carry line load currents and fault currents.

Pole-mounted switches generally consist of a switch body with sensors + an FTU (Feeder Terminal Unit). The switches discussed below fall under the category of pole-mounted disconnectors (isolators).

2. Classification of Pole-Mounted Switches

Pole-mounted switches can be classified from multiple dimensions. The core classification methods and characteristics are as follows:

By Interrupting Capacity:

- a. Pole-Mounted Disconnector (Isolator): No arc-extinguishing capability; cannot close or interrupt normal load current. Has a visible break (isolation gap). Its core purpose is to isolate lines to ensure safety during maintenance.

- b. Pole-Mounted Load Switch: Has basic arc-extinguishing capability; can close, carry, and interrupt normal load current (≤630A). Can carry but cannot interrupt fault current.

- c. Pole-Mounted Circuit Breaker: Strong arc-extinguishing capability; can close, carry, and interrupt normal load current (≤630A) and fault current (≥20kA).

- d. Pole-Mounted Fuse (Drop-Out Fuse): Core function is to interrupt short-circuit current; used for line short-circuit protection.

3. Pole-Mounted Disconnector (Isolator)

Also known as an "isolating knife switch," it is a control device without an arc-extinguishing mechanism. Its core function is to isolate the power supply to ensure the safe maintenance of other electrical equipment. Operation under load is not permitted (it can only make/break low-power circuits under specific conditions). It is one of the most widely used and frequently operated devices in high-voltage switching.

3.1 Core Uses

- De-energizing line equipment for maintenance, fault finding, cable testing, and reconfiguring operational modes.

- Once opened, it isolates the equipment under maintenance from the live line, creating a reliable insulation gap and providing a "visible, clear break indication" to ensure personnel safety.

- Serves as a demarcation switch between overhead lines and user property, or between cable lines and overhead lines.

- Installed on one or both sides of a tie load switch to facilitate fault finding, cable testing, and maintenance/replacement of the tie load switch.

3.2 Key Characteristics

- Advantages: Low cost, simple structure, durable.

- Limitations: Cannot operate under rated load/heavy load; cannot break or make load current and short-circuit current.

- Operating Procedure: For energizing: "Close the isolator first, then close the circuit breaker/load switch." For de-energizing: "Open the circuit breaker/load switch first, then open the isolator."

- Special Permissible Conditions: Can make/break the magnetizing current of no-load transformers (≤2A) and the capacitive current of no-load lines (≤5A).

- Technical Parameters: Typically, peak withstand current (dynamic stability) ≤40kA (must be verified during selection). Mechanical operating life is approximately 2000 cycles.

4. Pole-Mounted Load Switch

Equipped with a simple arc-extinguishing device, it can make and break circuits under load. It can interrupt certain load currents and overload currents but cannot interrupt short-circuit currents. It needs to be used in series with a high-voltage fuse (which cuts off the short-circuit current). Its functionality sits between an isolator and a circuit breaker. Its core uses are line sectioning and fault isolation.

4.1 Common Types and Characteristics

|

Type

|

Arc-Extinguishing Principle

|

Advantages

|

Applicable Scenarios

|

|

Gas-Production Load Switch

|

Solid gas-producing material generates gas under arc action, creating gas blast to extinguish arc.

|

Simple structure, low cost.

|

Scenarios with low operating frequency requirements.

|

|

Vacuum Load Switch

|

Vacuum arc extinction, often combined with SF₆ insulation.

|

Long life, maintenance-free, mechanical life ≥10,000 cycles.

|

Scenarios requiring frequent operation.

|

|

SF₆ Load Switch

|

SF₆ arc extinction + SF₆ insulation.

|

Excellent arc extinction/insulation performance, maintenance-free.

|

Scenarios requiring high reliability.

|

4.2 Mainstream Product Structural Features

- Vacuum Load Switch: Three-phase common tank type, equipped with VSP5 electromagnetic/spring operating mechanism. Can have built-in current transformers (CTs) and isolation gaps. Supports cable/terminal outgoing lines. Can be mounted hanging or sitting.

- SF₆ Load Switch: Three-phase common tank type. Can have built-in current transformers (CTs). Optional external isolation device. Supports cable/terminal outgoing lines. Can be mounted hanging or sitting.

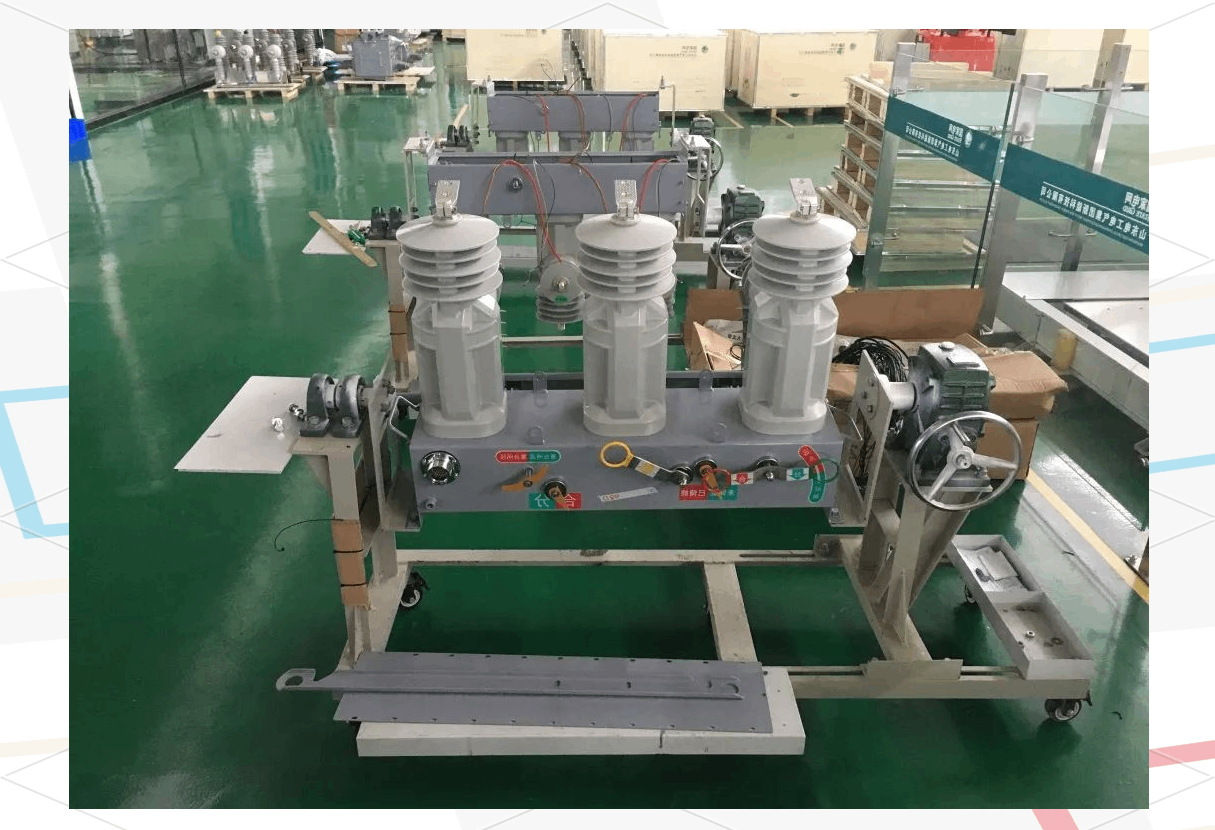

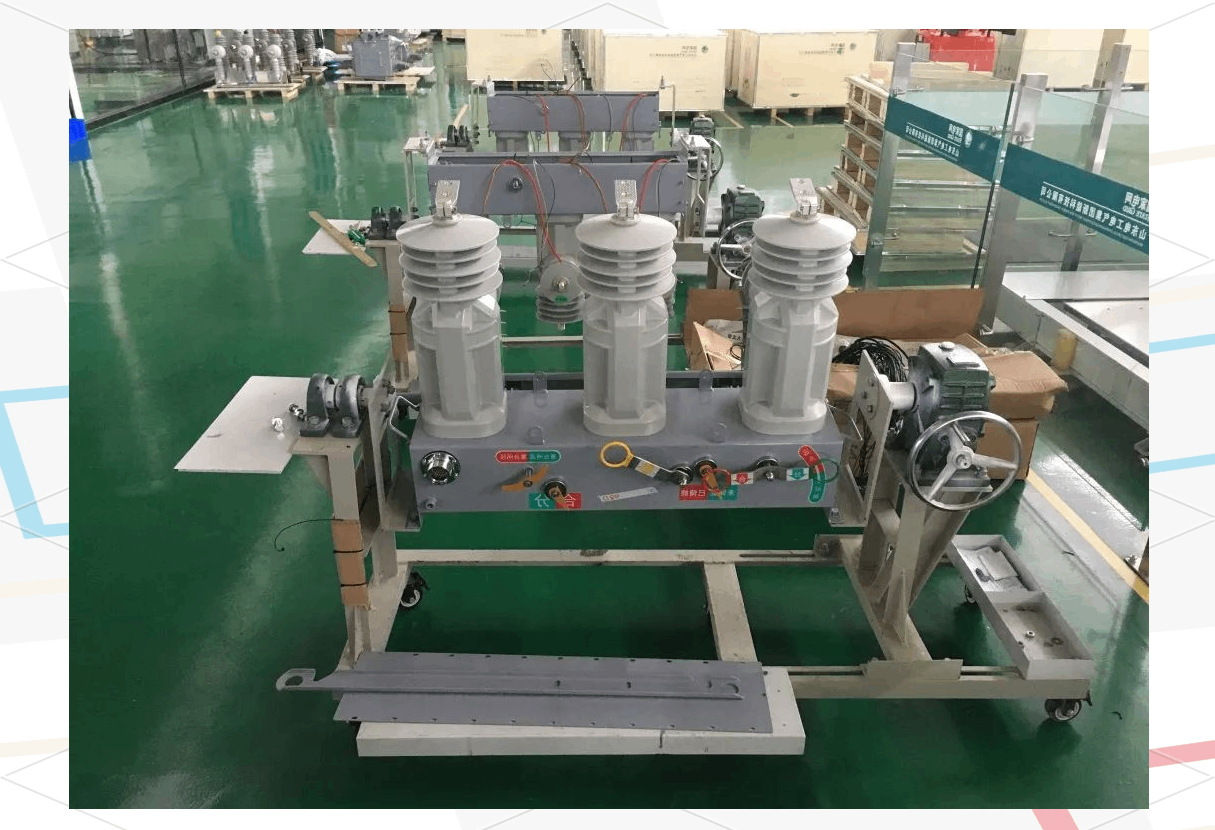

5. Pole-Mounted Circuit Breaker

A switching device with complete arc-extinguishing capability. It can close, carry, and interrupt normal circuit current, and can carry and interrupt abnormal circuit currents (overload, short-circuit) within a specified time. Its function is equivalent to a combination of a "fused switch + over/under thermal relay." Pole-mounted circuit breakers are commonly known as "reclosers" or "auto-reclosers." Installed on poles, they are core equipment for protection and control in distribution network sections.

5.1 Core Uses

- Sectionalizing, switching, control, and protection of distribution line segments; capable of actively interrupting and closing short-circuit currents.

- Normally used to open/close lines; during faults, automatically or manually (via relay protection devices) switches out faulty lines.

- Installed at responsibility demarcation points on 10kV overhead lines; can automatically clear single-phase earth faults and isolate short-circuit faults. A core device for distribution automation upgrades.

5.2 Classification and Mainstream Products

Classified by arc-extinguishing medium: Oil circuit breaker (largely obsolete), SF₆ circuit breaker, Vacuum circuit breaker (current mainstream).

Outdoor AC high-voltage intelligent vacuum circuit breakers are currently the preferred choice for distribution lines, featuring:

- Functions: Fault detection, protection control, communication capabilities.

- Operation Methods: Manual, electric, remote control, host computer remote operation.

- Composition: Body + operating mechanism + controller (may include built-in isolator).

- Optional Components: CT (Protection Current Transformer), ZCT (Zero-Sequence Current Transformer), PT (Voltage Transformer).

5.3 Vacuum Circuit Breaker Subtypes

- SF₆ Insulated Vacuum Circuit Breaker: Vacuum arc extinction + SF₆ insulation. Three-phase common tank. Spring operating mechanism. Can have built-in CTs. Optional external isolation device. Hanging or sitting mounting.

- Air Insulated Vacuum Circuit Breaker: Vacuum arc extinction + air insulation. Three-phase solid-pole type. Spring or permanent magnet operating mechanism. External CTs. Optional external isolation device. Sitting mounting.

6. Drop-Out Fuse

Commonly known as a "fuse cutout," it is the most commonly used short-circuit protection switch for branch lines and distribution transformers in 10kV distribution networks. It is economical, easy to operate, and suitable for outdoor environments. Widely used for protection and switching operations on 10kV lines and the primary side of distribution transformers.

6.1 Core Uses

- Installed on 10kV distribution branch lines: Limits the scope of power outages. Provides an isolator function due to its visible break, creating a safe environment for maintenance.

- Installed for distribution transformers: Serves as the main protection for transformers, safeguarding them against overload and short-circuit impacts.

6.2 Installation and Structure

- Installation Location: Can be installed on the source side of a load switch (preferred when fuses don't need frequent replacement, allows the load switch to isolate voltage) or on the load side.

- Core Components: Insulator, lower support base, lower moving contact, lower fixed contact, mounting plate, upper fixed contact, "duckbill" contact, upper moving contact, fuse tube.

7. Core Differences Between Pole-Mounted Switches

The key differences between various pole-mounted switches lie in three main dimensions: arc-extinguishing capability, types of interruptible current, and protection function. A detailed comparison is below:

|

Switch Type

|

Arc-Extinguishing Device

|

Interruptible Current Types

|

Carry Current Types

|

Protection Coordination Requirement

|

Core Purpose

|

|

Disconnector (Isolator)

|

None

|

Only system no-load current

|

Working current, short-circuit current (short time)

|

No protection coordination needed, used solely for isolation.

|

Safety isolation for maintenance, visible break.

|

|

Load Switch

|

Simple

|

Normal load current, overload current

|

Working current, short-circuit current (short time)

|

Requires series connection with fuse; fuse interrupts short-circuit current.

|

Line sectioning, normal load switching.

|

|

Circuit Breaker

|

Full

|

Normal load current, overload current, short-circuit current

|

Working current, short-circuit current (for specified time)

|

Requires coordination with relay protection device; protection issues trip command.

|

Fault clearance, comprehensive line protection.

|

|

Drop-Out Fuse

|

Simple

|

Short-circuit current, overload current

|

Working current (normal conditions)

|

Used alone, provides direct short-circuit/overload protection.

|

Short-circuit protection for branch lines & transformers.

|

Summary

- Disconnector (Isolator): Only breaks no-load current; provides a "visible break point" for safe maintenance.

- Load Switch: Breaks normal load current, not fault current; requires a fuse for fault protection.

- Circuit Breaker: Breaks both normal load and fault currents; requires relay protection coordination; core device for distribution network protection.

- Drop-Out Fuse: Specifically breaks short-circuit/overload currents; provides low-cost protection for branch lines and transformers.