1 Relevant Theories of Small Neutral Point Reactors in 500kV Substations

1.1 Definitions and Roles

A reactor is a key power system component that controls the phase relationship between AC current and voltage, divided into inductive and capacitive types. Inductive reactors limit short-circuit currents and improve stability; capacitive ones enhance transmission efficiency and voltage quality. A small neutral point reactor is a specialized type connected between a three-phase system's neutral point and ground.

In 500kV substations (critical for large-scale, long-distance power transmission), such reactors are vital. They effectively limit short-circuit currents, reducing losses and boosting stability. They also mitigate current/voltage fluctuations that could damage sensitive equipment, improving power quality. Additionally, they assist in fault detection/protection by coordinating with devices like circuit breakers and relays for faster, more accurate fault isolation.

1.2 Types and Characteristics

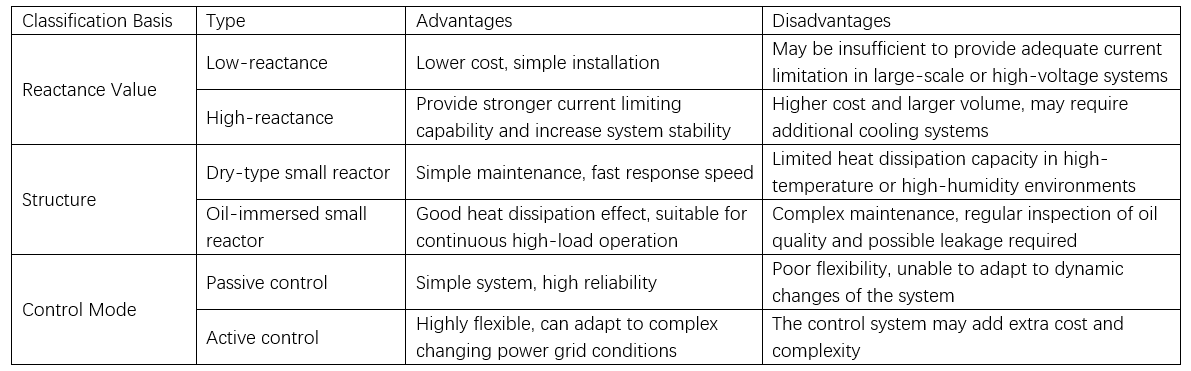

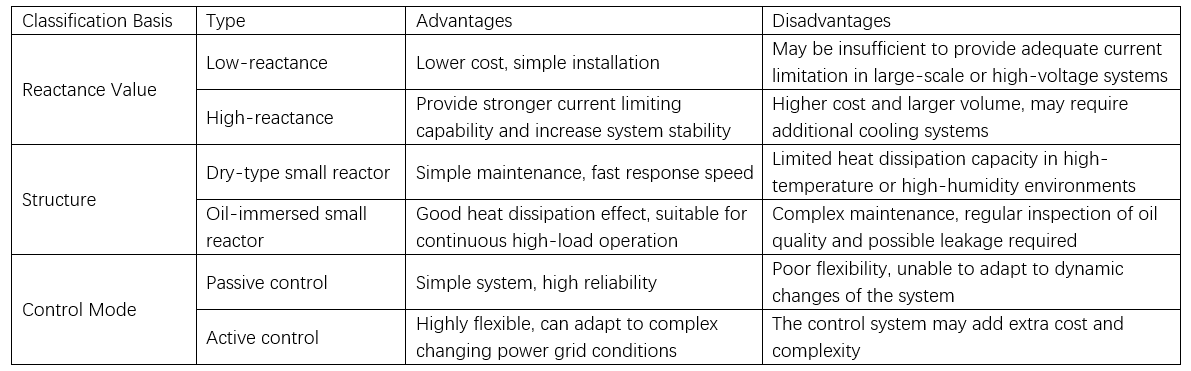

Different types of small reactors have their own unique advantages, disadvantages, and application scenarios. When selecting a small reactor for the neutral point of a 500kV substation, multiple factors need to be comprehensively considered, including the specific needs of the system, cost constraints, and maintenance complexity. Therefore, understanding the characteristics of each type of small reactor is a crucial step for effective selection.

In general, classification can be done using the following three methods: by reactance value, by structure, and by control mode, as shown in Table 1.

2 Selection Standards and Methods

2.1 Comparison of Domestic and International Standards

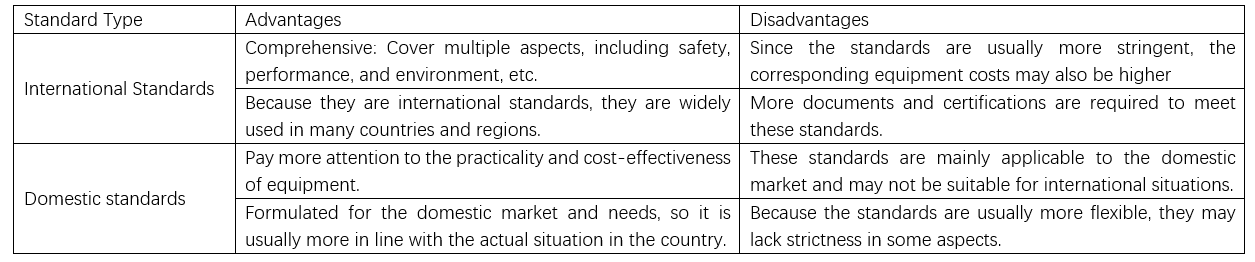

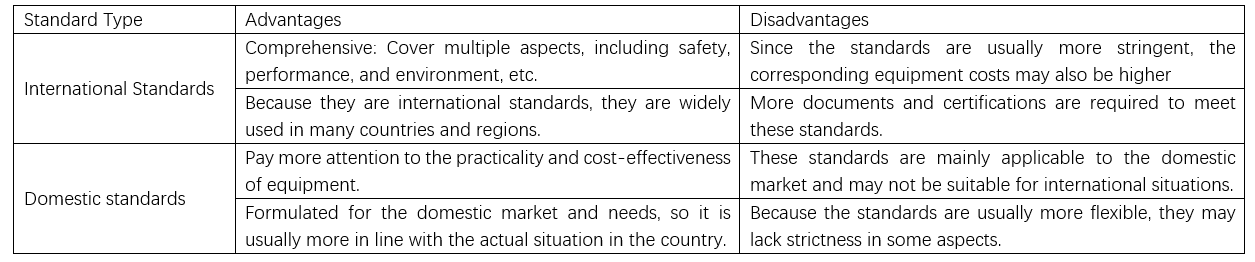

When selecting small neutral - point reactors for 500kV substations, understanding and comparing domestic and international standards is crucial. This ensures product quality/performance and meets regional/application - specific needs.

Internationally, the IEC (International Electrotechnical Commission) leads in formulating power equipment standards. IEC standards are more comprehensive and stringent, covering design, manufacturing, testing, and maintenance — often seen as global “golden standards”. In China, standards are usually set by the State Grid Corporation or relevant institutions. These prioritize practicality and cost - effectiveness but may be relatively lenient in aspects like environmental protection, as shown in Table 2.

2.2 Selection Methods and Procedures

In selecting small neutral-point reactors for 500kV substations, two key aspects are involved: computational simulation and experimental verification. Each has unique pros and cons, but combined, they enable comprehensive, accurate assessments to ensure successful selection.

The computation - simulation stage is vital. First, conduct demand analysis to clarify electrical parameters (current, voltage, frequency) as a basis for calculations. Use precise models/algorithms to determine key parameters like required reactance and rated current. Then, leverage software (e.g., PSS/E, DIgSILENT) for detailed system simulations. This verifies results and evaluates reactor performance under diverse conditions.

Advantages include predictability and cost - effectiveness — simulating pre - installation performance avoids wrong equipment choices, saving costs/time. Limitations: results rely heavily on model accuracy, and building accurate models demands professional software and strong technical expertise.

2.3 Experimental Verification

Unlike computational simulation, experimental verification directly assesses reactor performance. After selecting a reactor type/specification, prototype/sample tests first run in labs to check basic performance and reliability ⁵. Then, rigorous on - site tests follow — in actual 500kV substations, reactors face complex conditions, the ultimate test of performance/reliability.

The strength of experimental verification is direct observation of real - world performance. Analyzing real - condition data ensures reactors meet design/operation needs. But it has downsides: multiple experiments and long - term data collection drive up costs and time.

3 Application Case Analysis

3.1 Case Background

This case features a 500kV substation in a western city center, powering nearby commercial zones and residential areas. The region has a subtropical climate (15°C annual average temperature, 60% relative humidity), high power demand, a complex grid, and peak loads hitting 400MW.

3.2 Application Process

3.2.1 Selection and Installation

Selection is key to project success, so the stage gets heavy time/resource investment. The team does in - depth demand analysis, evaluating grid load traits, current/voltage needs, and special conditions (e.g., short circuits, overloads).

Based on this, they run calculations and simulations. Using software like PSS/E, they model reactor performance under diverse scenarios (short - circuit current limiting, system resonance, current imbalance). Simulations show a high - reactance, oil - immersed, actively controlled reactor suits best. A small neutral - point reactor (rated current 2000A, reactance 10Ω) of this type is tentatively chosen. To confirm, the team references domestic/international standards (e.g., IEC), local power standards, and prior research in similar cases.

After getting approval from all stakeholders (power companies, design institutes, equipment suppliers), installation starts. A professional team handles physical installation, electrical connections, and system integration. Post - installation, strict on - site tests/commissioning check reactance accuracy, system response speed, and coordination with other power equipment for stable operation.

3.2.2 Operation and Monitoring

Once the equipment is put into operation, an advanced monitoring system is used for real - time data tracking and performance evaluation. It includes not only the monitoring of current and voltage but also the monitoring of equipment temperature, oil quality, and other key parameters.

3.2.3 Maintenance and Optimization

Due to the selection of oil - immersed type and active control, the maintenance of the equipment is relatively simple. Maintenance is only required once a year, mainly including oil quality inspection and calibration of electrical parameters. Based on the operation data, necessary system optimizations are also carried out to further improve the performance and reliability of the equipment.

3.3 Benefit Analysis

3.3.1 Economic Benefits

Cost savings: Owing to careful selection and optimization, the reactor demonstrates a high degree of stability and reliability during operation, greatly reducing the maintenance and replacement costs caused by equipment failures. According to statistics, compared with traditional reactors, the maintenance cost saved within one year is about 20%.

Efficiency improvement: The application of the reactor significantly improves the operation efficiency of the power grid. According to preliminary data, the overall efficiency of the system has increased by about 5%, which means higher power output and lower operation costs.

Return on investment: Considering the equipment cost, operation cost, and efficiency improvement comprehensively, the investment return period of this reactor is expected to be within three years, which is a quite satisfactory result.

3.3.2 Technical Benefits

System stability: The application of the reactor significantly improves the stability of the system. In case of short circuits or other abnormal situations, the reactor can effectively limit the current and protect the power grid and equipment from damage.

Reliability: Due to the selection of the high - reactance, oil - immersed, and actively controlled reactor, the equipment demonstrates extremely high reliability under various working conditions. No failures or abnormalities occurred within one year, greatly improving the reliability of the power grid.

Flexibility and adaptability: The active control system enables the reactor to quickly respond to changes in the power grid, such as load fluctuations and voltage changes, which increases the flexibility and adaptability of the system.

4 Conclusion

This research comprehensively explores the selection, application, and benefits of small neutral - point reactors in 500kV substations. It shows that proper reactor selection is crucial for grid stability and operational efficiency. This principle applies to substations of other voltage levels and types too.

Compared with previous studies, this research emphasizes practical application and benefit analysis, providing more evidence from real - world data and cases. It enriches the theoretical research system of small neutral - point reactors and offers practical support for power system design and optimization.