I. Introduction to Cable Grounding Loop Current

Cables rated 110 kV and above use a single-core structure. The alternating magnetic field generated by the operating current induces a voltage on the metallic sheath. If the sheath forms a closed circuit through the earth, a grounding loop current will flow on the metallic sheath. Excessive grounding loop current (loop current exceeding 50 A, more than 20% of the load current, or a ratio of maximum-to-minimum phase current greater than 3) not only affects cable ampacity and service life, but severe heating from the current can burn grounding wires or grounding boxes. Failure to promptly rectify such issues may trigger serious power grid accidents.

II. Factors Influencing Cable Grounding Loop Current

The main factors affecting cable grounding loop current are as follows:

Contact Resistance of the CablePoor welding or bad connections that increase the contact resistance in one phase will significantly reduce the grounding loop current in that phase. However, the loop currents in the other two phases do not necessarily decrease correspondingly. As the resistance increases, the total grounding current does not necessarily decrease either.

Grounding ResistanceAs the sum of the grounding resistance and earth return path resistance increases, the grounding loop current in each phase decreases. However, excessively high grounding resistance can cause poor contact at the grounding point, leading to heating and power losses.

Cable Grounding MethodTo limit the induced voltage on the cable's metallic sheath, high-voltage cables typically use grounding methods such as single-point grounding, both-ends grounding, or cross-bonding for the sheath or screen. For longer high-voltage cable lines, the cross-bonding method is effective in limiting grounding loop current.

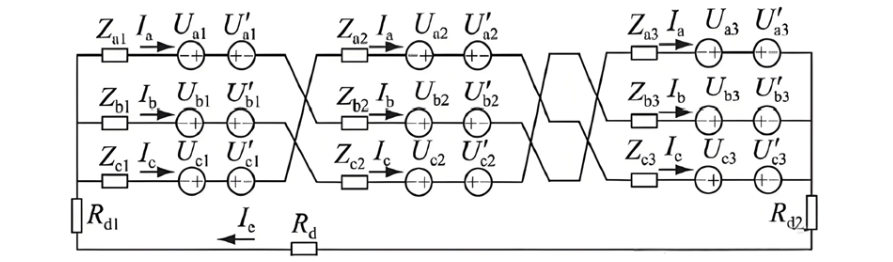

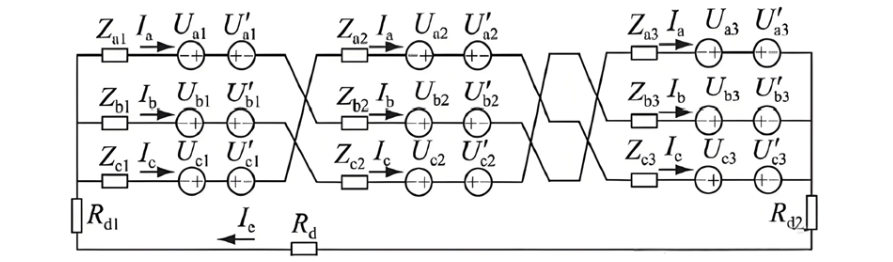

Among these, Ia, Ib, and Ic are the current values flowing through the metallic sheaths of the A, B, and C phase high-voltage cables, respectively; Ie is the current flowing through the earth return path; Rd is the equivalent resistance of the earth return path, and Rd1 and Rd2 are the grounding resistances at both ends of the cable sheath. Under normal circumstances, the operating currents of the three-phase cables can be assumed equal in magnitude. By utilizing the phase difference between the three-phase currents, the induced voltages on the metallic sheaths within a complete cross-bonded section can be canceled out, thereby achieving the purpose of reducing grounding loop current.

(1) Cable Segment Lengths, Cable Arrangement Methods, and Phase Spacing

Cables generally adopt a cross-bonding grounding method to reduce grounding loop current. In engineering practice for cable duct installations, it is common for the individual segments of sheath cross-bonding to have different lengths and different arrangement configurations. Under the same conductor current, the induced voltage on the metallic sheath for horizontally or vertically arranged cables per unit length is higher than that for cables arranged in a right-triangular configuration. Therefore, in unequal-length segmented cables, using the triangular arrangement (which produces lower induced voltage) for longer cable sections and the horizontal or vertical arrangement (which produces higher induced voltage) for shorter sections helps reduce the overall induced voltage in the longer segments. By appropriately selecting the arrangement for each sub-segment, the voltage imbalance caused by differences in cable length can be balanced, thus reducing sheath loop current.

III. Analysis of Abnormal Cable Grounding Loop Current

A transposition failure will result in the loss of a current vector in one direction, causing a significant increase in sheath grounding current, which may ultimately lead to operational faults. In different transposition failure scenarios, the magnitudes and phases of the three-phase currents differ considerably. A transposition failure is typically characterized by two phases having relatively similar grounding currents, while the current in the other phase is significantly smaller—generally about half of the smallest grounding current in the other two phases.

(1) Water Ingress in the Box

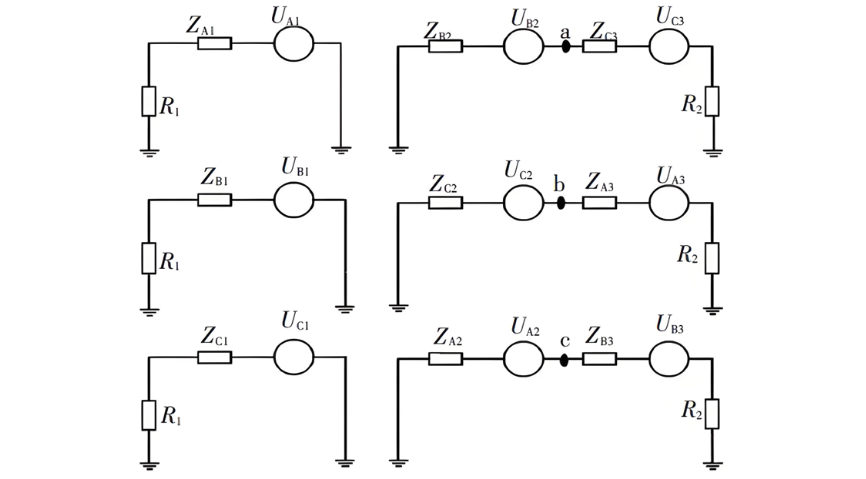

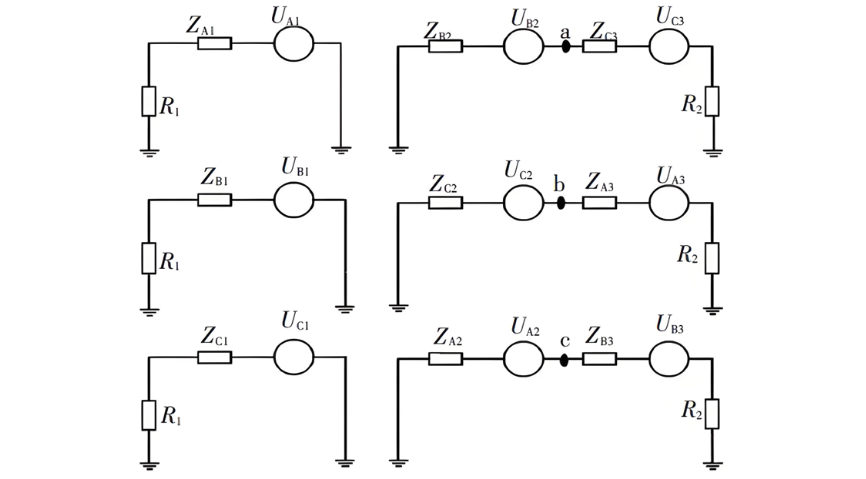

When water enters a cross-bonding joint box, the water inside creates a low grounding resistance, and the connection between the internal and external water effectively provides a direct grounding path for current. As shown in the figure below, a direct ground occurs at point a, b, or c.

Prolonged rainfall can lead to long-term water accumulation in cable trench cross-bonding boxes. Especially when both boxes are flooded, the grounding current can easily reach hundreds of amperes, causing a sudden surge in sheath current and a rapid rise in internal cable temperature. When only one box is flooded, the three-phase currents in the affected loop show slight differences and increase by approximately 2.5 times compared to normal, non-fault conditions.

(2) Coaxial Cable Breakage

Lines using cross-bonding grounding are generally longer than 1 km. If the coaxial cable breaks, a voltage of over one hundred volts can be generated at the break point, posing a significant threat to the line. It also prevents the associated metallic sheaths from forming a closed loop, thereby stopping loop current from flowing in the sheath.

IV. Typical Case Studies of Abnormal Cable Grounding Loop Current

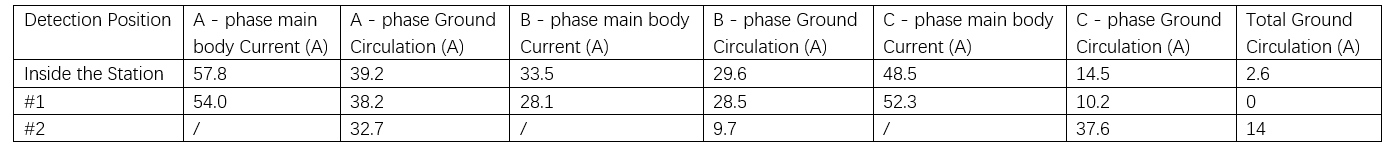

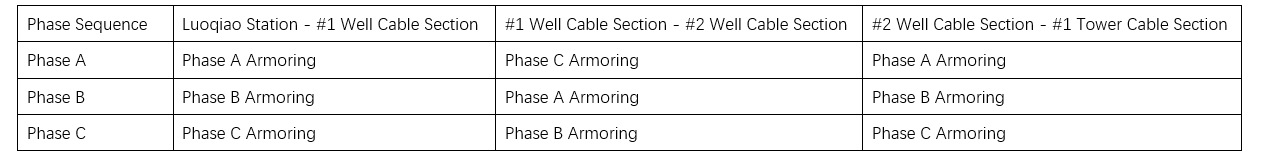

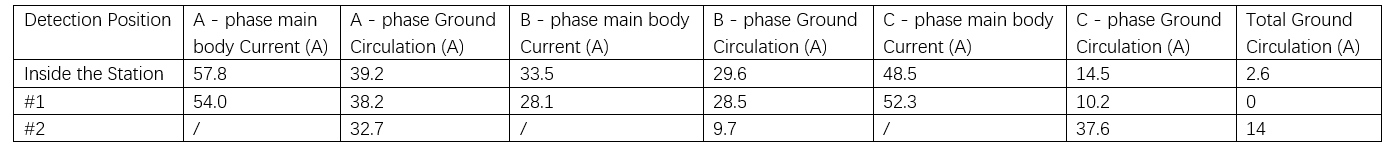

A certain 110 kV line is a hybrid overhead-cable line. The cable model is YJLW03-64/110-1×800 mm². The line was commissioned in September 2014 and is approximately 1220 meters long. On December 27, 2016, the cable grounding system was modified to use a cross-bonding grounding method. The complete cross-bonded section consists of the substation, Box #1, Box #2, and the external transmission tower. Boxes #1 and #2 are cross-bonding boxes, while all other points are directly grounded. The measured grounding loop current results are shown in the table below:

According to clause 5.2.3 of Q/GDW 11316 "Power Cable Line Test Regulations": the ratio of grounding loop current to load current shall be less than 20%; the ratio of the maximum to minimum single-phase grounding loop current shall be less than 3. When the load current is 57.8 A, the sheath currents of phases A, B, and C at the station's direct grounding box, Box #1, and Box #2 all severely exceed the requirements specified in the regulations. Furthermore, the ratio of the maximum to minimum single-phase grounding loop current (37.6/9.7 = 3.88) is also greater than 3.

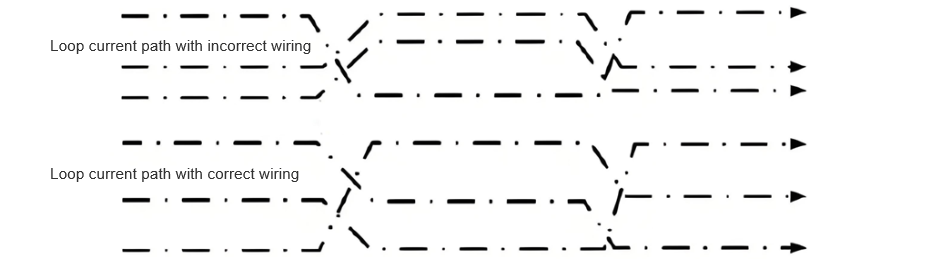

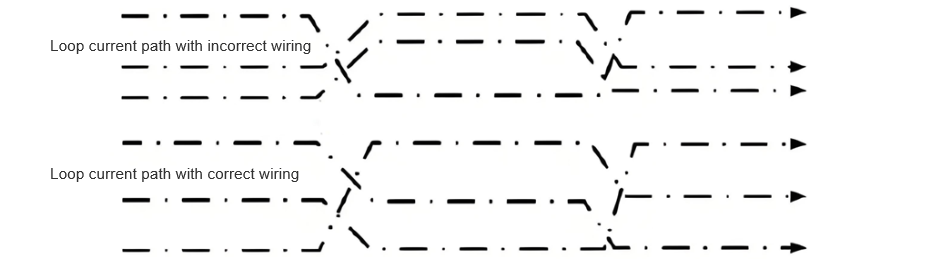

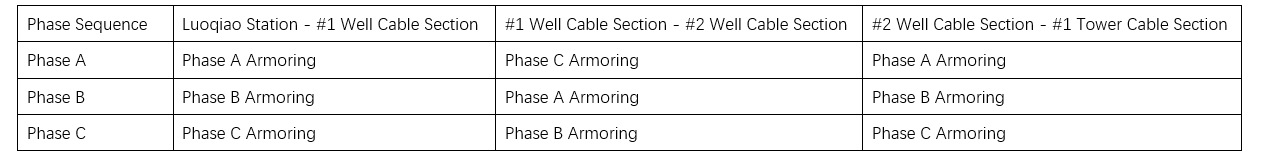

Based on the analysis of the measured grounding loop current data in the table above: the A-phase grounding loop current in Manhole #1 is 38.2 A, corresponding to the C-phase grounding loop current of 37.6 A in Manhole #2; the B-phase grounding loop current in Manhole #1 is 28.5 A, corresponding to the A-phase grounding loop current of 32.7 A in Manhole #2; the C-phase grounding loop current in Manhole #1 is 10.2 A, corresponding to the B-phase grounding loop current of 9.7 A in Manhole #2. The three-phase grounding loop currents flow through the following paths: the A-phase grounding loop current does not flow through the B-phase armor, the B-phase grounding loop current does not flow through the C-phase armor, and the C-phase grounding loop current does not flow through the A-phase armor, as illustrated in the figure and table below.

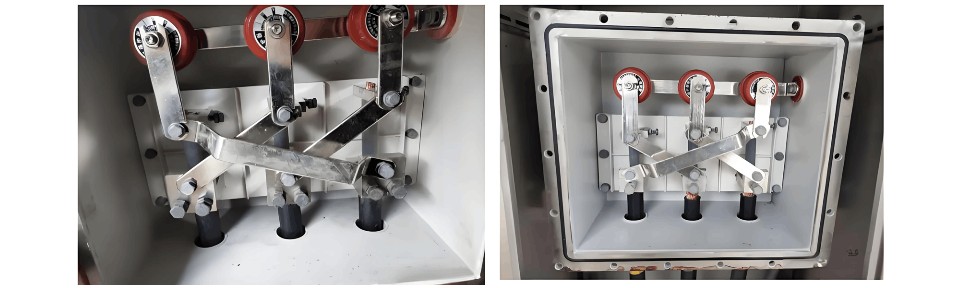

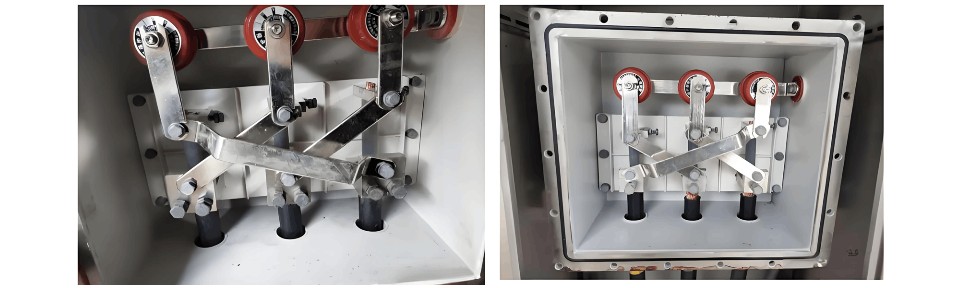

On-site inspection revealed that the internal cross-bonding configuration in the grounding box of Cable Maintenance Manhole #1 is "ABC to BCA", with phase sequence A, B, C. The internal cross-bonding configuration in the grounding box of Manhole #2 is "ABC to CAB" , also with phase sequence A, B, C. No signs of moisture or burn damage were found on the cable sheath protectors or insulating components. These are shown in the figures below, respectively:

Therefore, the cause of the abnormal grounding loop current in this 110 kV XX line cable section is incorrect wiring of the copper busbars inside the cross-bonding boxes, which prevented the cable outer sheaths from achieving actual cross-bonding. This resulted in excessive grounding loop current in the local cross-bonded section.

After correcting the wiring configuration, the cable's grounding loop current complies with the requirements of Q/GDW 11316-2014 "Power Cable Line Test Regulations".