1 Research on Cable Laying and Wiring Construction Technology of Photovoltaic Power Station

1.1 Data Collection

Before constructing the BIM model for cable laying, it is necessary to deeply master the detailed parameters of the involved equipment specifications, materials used in construction, and site conditions, aiming to improve the accuracy of model construction. To ensure that the BIM model can accurately reflect the actual situation of the construction site, the core lies in accurately collecting and entering the specific technical parameters of key equipment. These include the precise dimensions of cable trenches, the detailed specifications of distribution boxes, the outer diameter dimensions of cables, and the specific parameters of wire slots. The relationship between these parameters and the cable model should follow the following rules:

In the formula, P is the set of key parameters; I is the precision of the cable - laying model; f maps P to I; and g is the adjustment function. Accurate parameter acquisition directly affects subsequent model building and practicality. During data collection, device parameters are closely interrelated. Changes in any single device’s data may trigger chain reactions, requiring timely adjustment of related parameters. Thus, in the data collection stage, flexibly adjust strategies based on on - site conditions to ensure data consistency and accuracy.

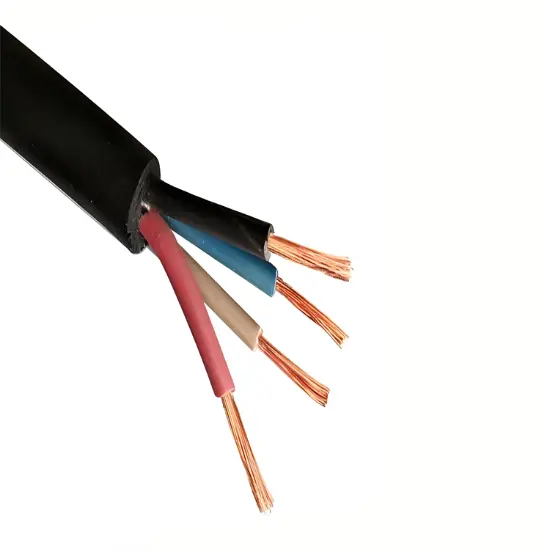

1.2 Building the Cable Model

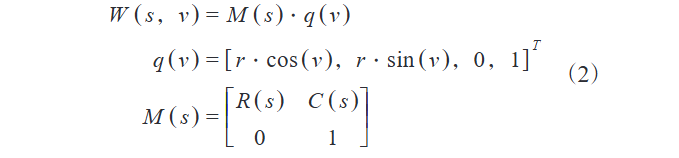

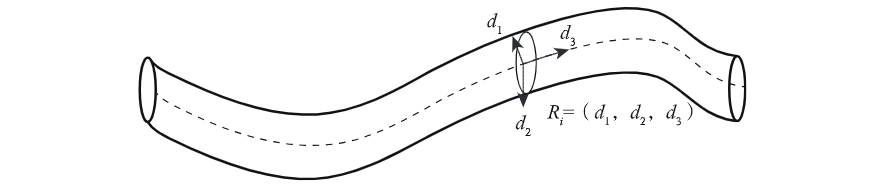

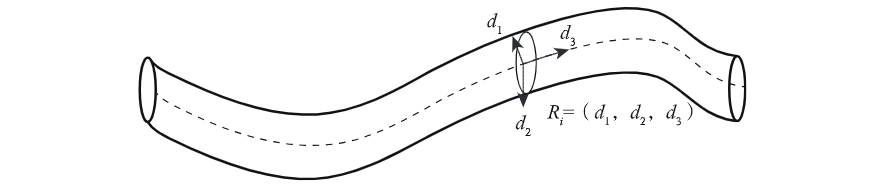

In construction, conductors form cables after sheathing. To connect cables to device terminals, install connectors at cable ends. A cable’s geometric model is an envelope from scanning its cross - section along the centerline. Simplify the cross - section to a circle (radius r), and use R(s) = (d1(s), d2(s), d3(s)) to define the local coordinate frame on centerline S. The cable’s geometry is precisely expressed via a parameterized equation, describing the envelope surface construction.

In the formula, W represents the local boundary matrix; C(s) represents the global coordinate positioning point; M(s) represents the rotation transformation matrix. The cable geometric model built based on this formula is shown in Figure 1.

In Figure 1, the dashed line S clearly marks the cable’s central axis. A feature point on S is taken as node q, where a local coordinate system R is built to describe the cross - section’s directional properties. Specifically, d1 (unit vector in the main normal direction) defines the cross - section’s main normal orientation; d2 (unit vector in the binormal direction, perpendicular to d1 refines the direction description; d3 (unit vector in the tangent direction along S) shows the cable’s extension trend at q. The cross - section at q is assumed circular with radius r0, forming a complete geometric model with direction vectors for subsequent cable instance analysis.

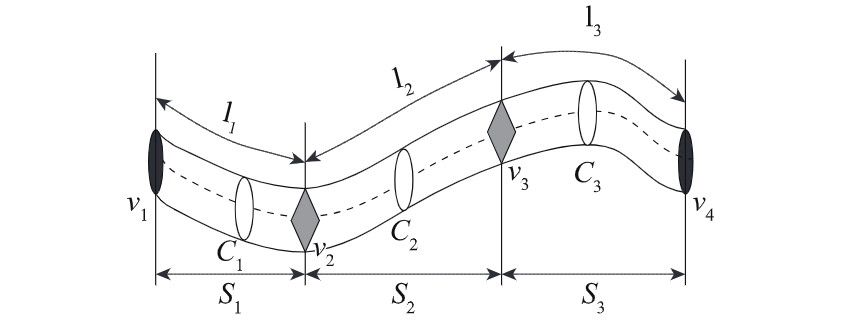

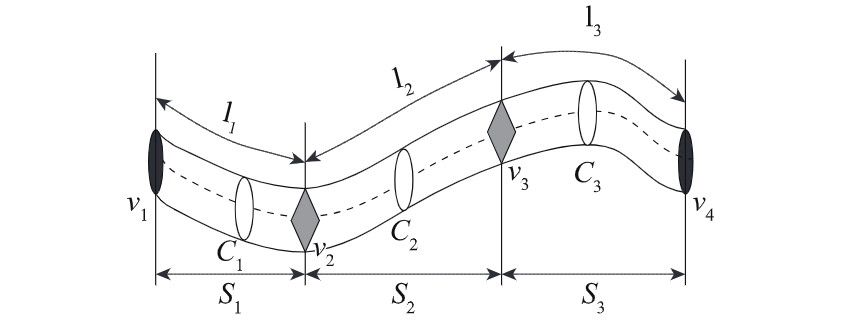

As shown in Figure 2, the cable instance is defined by four vertices v1–v4, dividing it into three segments l1: v1–v2; l2: v2–v3; l3: v3–v4, with v1 and v4 as endpoints. For each segment, its cross - section’s directional properties and shape are determined by its position/length on S and the geometric model. Thus, segments l1–l3 correspond to cross - sections C1–C3, together forming the cable’s geometric representation.

1.3 Cable Laying

Integrating details from Figures 1 and 2 allows accurate grasping of cable geometric modeling and segmentation features. The model precisely depicts core geometric elements (central axis, cross-sectional shape, directional attributes) and enables in-depth cable analysis via refined segmentation, providing a theoretical basis for efficient laying.

In pre - laying preparation, derive total lengths of cables of various specs based on the model. Organize data into standardized tables by cable type, supplying accurate info and guidelines for construction. For laying method, this project adopts direct burial to ensure professionalism and efficiency.

When laying in cable trenches, place a uniform sand/fine soil cushion to keep the cable’s bending radius within limits. Use electric winches for traction. When laying multi - core cables, strictly follow curvature radius restrictions:

In the formula, rmin represents the safe bending limit of the cable; cr represents the minimum safe turning radius of the cable. After completing the cable laying work, it is necessary to formally submit an application for hidden project acceptance to the department responsible for project quality inspection. Once the acceptance procedure is successfully passed, evenly lay fine soil on both the upper and lower sides of the cable as a protective layer, and then cover the cable with a cable cover. In addition, when planning the cable route, priority should be given to having the route closely adhere to the surface of wiring - allowable obstacles:

In the formula, qi is a specific node on the cable path centerline; OS is the obstacle surface node; Rr is the cable radius; Inter dis is the shortest distance between points.Before backfilling, review to confirm all hidden projects meet standards. Then compact the backfill to ensure its density and stability, complying with specs.

After compaction, bury direction marker stakes at key positions (cable intersections, connections, turns). Wrap cables with hemp for protection. When direct - buried cables pass through buildings, check outdoor - indoor pipe height differences; apply waterproofing if outdoor pipes are higher to ensure laying safety.

1.4 Cable Wiring

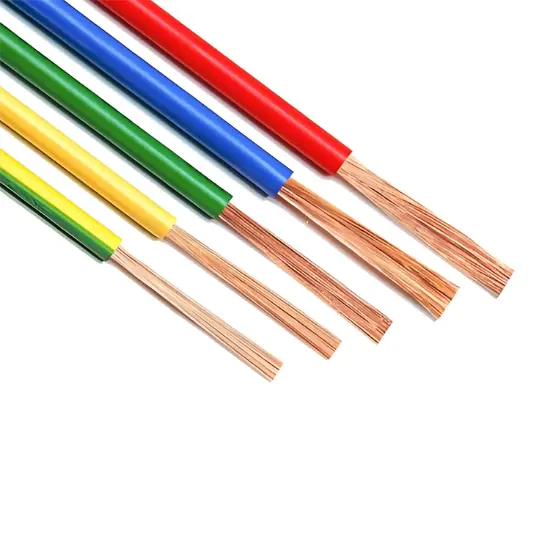

As a key link in photovoltaic power station construction, cable wiring must follow strict specs/procedures to ensure stable, reliable, and safe electrical connections.

First, prepare complete/qualified tools (wire strippers, crimping pliers, insulating sleeves, terminals, insulating tape) and materials. Ensure cables meet design specs, pass quality checks (no damage, intact insulation).

Before wiring, precisely strip cables: use wire strippers to remove outer sheaths/inner insulation per terminal requirements, expose conductors (remove burrs/oxides). Select suitable terminals based on conductor cross-sections and wiring needs. The formula is as follows:

In the formula, T is the terminal type; A is the cable conductor cross-sectional area; R denotes wiring parameters; S is the mapping function. Use crimping pliers to firmly crimp conductors and terminals, ensuring no loosening or poor contact. During wiring, strictly follow design drawings and specifications to accurately connect crimped terminals with equipment terminals, ensuring tightness.

For multi-core cables, match colors/numbers to avoid misconnections. After wiring, wrap connections with insulating sleeves/tape to enhance insulation and prevent intrusion of moisture or dust. In summary, cable wiring is critical to photovoltaic power station construction, requiring strict adherence to specifications to ensure quality and safety, laying a solid foundation for stable operation.

2 Experimental Analysis

To verify the effectiveness and feasibility of the proposed cable laying and wiring technology for photovoltaic power stations, it is compared with traditional methods.

2.1 Experimental Objects

The experiment is conducted under laboratory conditions using MATLAB for path planning simulation. Twenty standardized cable laying and wiring tasks are selected and divided into 4 groups (5 tasks each) to reduce random errors via statistical dispersion, enhancing result stability.

2.2 Experimental Preparation

Hardware includes computers with 500GB storage, 32GB memory, and Windows 10. These are debugged and optimized to ensure stable operation, accurately simulating real-world conditions for reliable results.

2.3 Experimental Results and Analysis

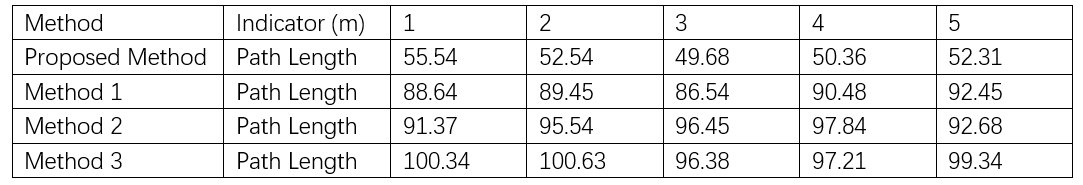

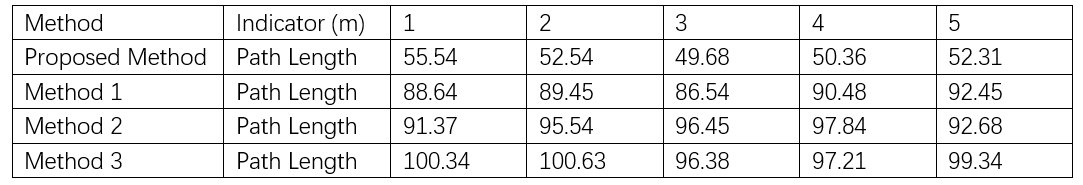

Three methods are compared with the proposed one; results are shown in Table 1.

3 Conclusion

Analyzing Table 1 data shows the proposed cable laying/wiring solution has remarkable advantages. Its path design (≈50m) is 40m, 45m, and 50m shorter than methods in 1, 2, 3. This not only proves efficient path planning but also highlights huge application potential in photovoltaic power station projects, providing valuable references for the power industry.

This paper explores cable laying/wiring for photovoltaic power stations, using BIM modeling to boost efficiency and safety. Experiments show the method outperforms traditional ones in path planning—shortening lengths and improving quality. It supports photovoltaic construction and powers sustainable industry development.

In the future, integrating intelligent construction and big data will make these technologies smarter and more efficient, driving a greener, low - carbon power industry. We expect more innovation to optimize processes, cut costs, and upgrade the global energy structure.