I. What is a Grid Voltage Overvoltage Fault?

Grid voltage overvoltage refers to a phenomenon in power systems or circuits where the voltage exceeds the normal operating range.

Generally, under power frequency, if the RMS (Root Mean Square) value of the AC voltage rises to more than 10% above the rated value and lasts for more than 1 minute, it can be determined as a grid voltage overvoltage fault.

For example, in China’s common 380V three-phase grid system, if the voltage exceeds 418V and persists for a certain period, it may trigger a grid voltage overvoltage fault.

In photovoltaic (PV) power stations, grid-connected inverters are responsible for real-time monitoring of grid voltage.

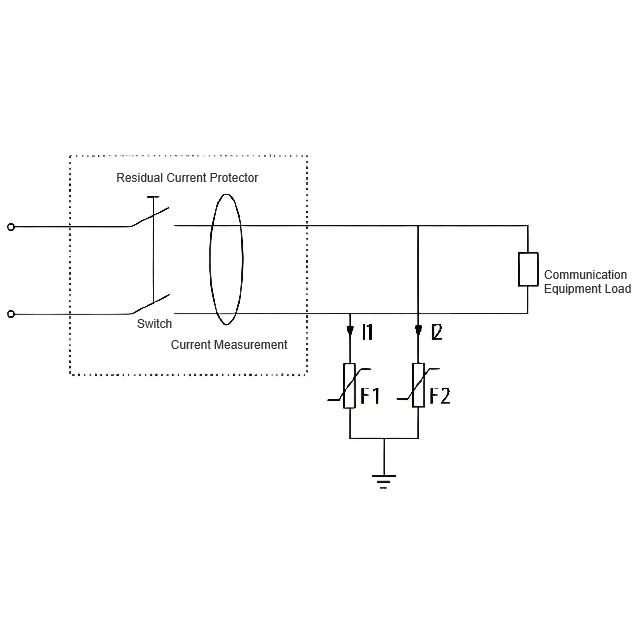

Inverters are usually equipped with high-precision voltage sensors to collect real-time grid voltage signals. These sensors transmit the collected voltage signals to the inverter’s control system, which analyzes and processes the signals to determine whether the grid voltage is within the specified range.

Once the grid voltage is detected to exceed the preset safe range, the inverter will immediately activate a protection mechanism, shut down, and disconnect from the grid to prevent overvoltage from damaging equipment and ensure the safety of both equipment and operators.

Additionally, in some large-scale PV power stations, dedicated power quality monitoring devices are installed to conduct comprehensive, real-time monitoring of various grid parameters, enabling timely detection and handling of power quality issues such as voltage overvoltage.

II. Causes of Voltage Overvoltage Faults

(1) Line Factors: Impact of Cable Impedance

Cables between the inverter and the grid connection point play a key role in power transmission.

If the cable is too thin, its resistance increases. According to Ohm’s Law (U = I×R), with a constant current, higher resistance leads to greater voltage drop, which in turn raises the AC output voltage on the inverter side.

Excessively long cables also increase resistance, causing similar voltage elevation issues. For instance, in PV power stations in remote areas where the grid connection point is far away, using cables of inappropriate specifications can easily lead to voltage overvoltage faults due to excessive cable impedance.

If cables are tangled, their inductance increases. In AC circuits, inductance impedes current flow, further disrupting voltage distribution and potentially triggering voltage overvoltage.

Wiring Errors

During the initial installation of a PV power station, incorrect AC cable wiring (e.g., connecting the neutral terminal to the live wire) can cause abnormal voltage. This may result in the inverter detecting a voltage that does not match the actual grid voltage, thereby triggering the overvoltage protection mechanism.

After the inverter has been in operation for a period, loose or poor connections in grid-side cables can increase contact resistance. According to Joule’s Law (Q = I²Rt, where Q is heat, I is current, R is resistance, and t is time), higher contact resistance generates more heat, leading to local temperature rise. This impairs the electrical performance of the line, causing a transient voltage increase in the inverter and triggering a voltage overvoltage fault.

(2) Grid Structure and Load Factors: Conflict Between Grid Capacity and Load Absorption

In some regions, especially remote rural areas or areas with underdeveloped grid infrastructure, the grid’s load absorption capacity is limited. When the installed PV capacity in the same power distribution area is too large, a large amount of PV-generated power is fed into the grid. If the grid cannot absorb this power in a timely and effective manner, grid voltage will rise.

Transformer-Related Issues

Transformers play a crucial role in voltage conversion and power distribution in the grid:

If the transformer is far from the grid connection point, its output voltage is usually raised to compensate for line voltage loss and ensure normal voltage in areas far from the transformer. However, this may cause excessive voltage at the grid connection point near the transformer.

Unreasonable transformer tap settings or operational faults (e.g., poor contact of the tap changer) can affect the transformer’s turns ratio, leading to abnormal elevation of the output voltage and triggering a grid voltage overvoltage fault.

(3) Inverter-Related Factors: Initial Settings and Operational Faults

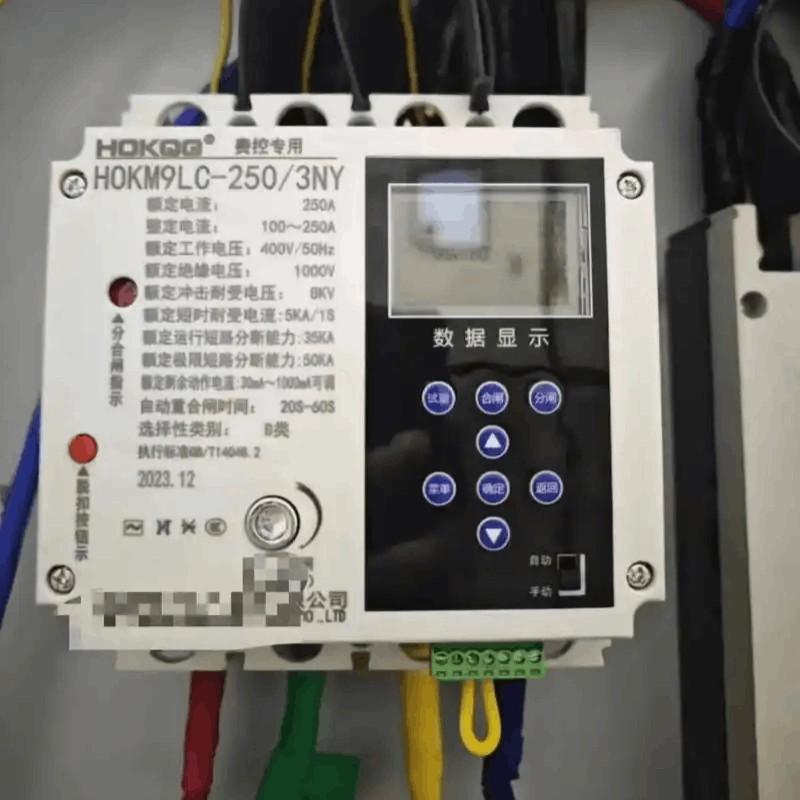

Inverters leave the factory with a default voltage protection range. In practical applications, if this preset range does not match the actual local grid conditions, misjudgment may occur. For example, if the grid voltage fluctuates within a normal range but the inverter’s voltage protection threshold is set too low, the inverter will frequently report overvoltage faults.

During long-term operation, inverters may experience hardware failures (e.g., damaged voltage sampling circuits, faulty control boards). These faults cause inaccurate grid voltage detection by the inverter, leading to incorrect activation of the overvoltage protection mechanism and inverter shutdown.

Multi-Inverter Connection Issues

In large-scale PV power stations, multiple inverters are often connected to the grid simultaneously. If multiple single-phase inverters are concentrated on one phase, the current on that phase will be excessively high, causing grid voltage imbalance and elevating the voltage of that phase.

III. Hazards of Voltage Overvoltage Faults to PV Power Stations and the Grid

(1) Damage to PV Power Station Equipment: Increased Risk of Inverter Faults

When grid voltage is overvoltage, electronic components inside the inverter bear voltage exceeding their rated value, accelerating component aging or even causing direct damage.

For example, power switching devices in inverters (such as IGBTs, Insulated Gate Bipolar Transistors) experience increased voltage stress during turn-on and turn-off under overvoltage conditions, making them prone to breakdown and rendering the inverter inoperable.

Additionally, overvoltage may cause faults in the inverter’s control circuit, impairing its ability to precisely control output voltage and current and further reducing the inverter’s performance and reliability.

Shortened PV Module Lifespan

Excessively high grid voltage can be fed back to the PV module side through the inverter, increasing the operating voltage of the modules. Long-term operation of PV modules under high voltage can alter the performance of their internal semiconductor materials, leading to issues such as hot spots and microcracks.

(2) Impact on Grid Stability: Deteriorated Power Quality

Grid voltage overvoltage degrades power quality and causes harmonic pollution. When voltage exceeds the normal range, nonlinear loads in the power system generate additional harmonic currents, which in turn further disrupt grid voltage, creating a vicious cycle. Harmonics increase heat generation in electrical equipment, reduce service life, and may interfere with the normal operation of communication systems, undermining the overall stability of the power system.

(3) Power Generation Loss and Reduced Economic Benefits: Inverter Shutdown and Derated Operation

When an inverter detects grid voltage overvoltage, it shuts down for protection or operates at reduced power to ensure equipment safety. Inverter shutdown causes the PV power station to stop generating electricity entirely, resulting in direct power generation loss.

Increased Long-Term Operation and Maintenance (O&M) Costs

Damage to PV power station equipment (e.g., inverters and PV modules) caused by voltage overvoltage faults requires timely repair and replacement. This not only increases short-term repair costs but also necessitates more frequent equipment replacement in the future due to shortened service life, raising long-term O&M costs.

IV. Effective Solutions to Voltage Overvoltage Faults

(1) Pre-Construction Planning and Design Optimization: Comprehensive Grid Survey and Assessment

In the pre-construction phase of a PV power station, a comprehensive and detailed survey and assessment of the local grid should be conducted. Key parameters such as grid structure, capacity, load conditions, and voltage fluctuation range should be thoroughly understood. Professional power analysis software should be used to simulate and analyze the potential impact of the PV power station on the grid after connection.

For example, tools like PSCAD (Power System Computer-Aided Design) or ETAP (Electrical Transient Analyzer Program) can simulate grid voltage changes under different PV installed capacities, connection locations, and connection methods. This helps determine the most reasonable PV power station construction plan, ensures healthy voltage at the grid connection point, and reduces the risk of voltage overvoltage faults at the source.

Rational Planning of PV Installed Capacity

Based on the grid’s load absorption capacity and transformer capacity, the installed capacity of the PV power station should be planned rationally. Avoid overconcentrating PV equipment in the same power distribution area to prevent voltage elevation caused by excessive PV power that the grid cannot absorb.

Optimization of Inverter Connection Methods

For PV power stations with multiple inverters, the inverter connection method should be optimized. Avoid concentrating multiple single-phase inverters on one phase; instead, distribute them evenly across the three grid phases to achieve multi-point grid connection. This balances three-phase current and reduces voltage imbalance and elevation caused by excessive single-phase current.

(2) Equipment Selection, Installation, and Commissioning Specifications: Use of High-Quality Cables and Rational Wiring

In PV power station construction, high-quality cables that meet national standards should be used. Cable specifications and cross-sectional area should be selected based on actual transmission power and distance.

For long-distance grid connection, a larger cable cross-sectional area is required to reduce line impedance and voltage drop.

Meanwhile, wiring should be rational to avoid excessively long, tangled, or unnecessarily bent cables. During wiring, cable trays or ducts can be used to protect and organize cables, ensuring safe cable operation.

For example, in large-scale PV power stations, underground cable laying can be adopted, and cable routes can be planned rationally to reduce cable length and crossings, improving power transmission efficiency and lowering the probability of voltage overvoltage faults.

Accurate Inverter Selection and Installation

When selecting inverters, full consideration should be given to local grid conditions. Inverters with a wide voltage adaptation range, reliable overvoltage protection, and high power conversion efficiency should be chosen.

During installation, ensure correct AC wiring of the inverter to avoid voltage abnormalities caused by swapping phase and neutral wires.

Rational Transformer Configuration and Maintenance

Transformers with good voltage regulation performance should be selected to enable timely adjustment when grid voltage fluctuates. Meanwhile, daily maintenance and monitoring of transformers should be strengthened. Transformer parameters such as tap changers, windings, and oil levels should be inspected regularly to ensure normal transformer operation.

For transformers far from the grid connection point, on-load tap changers can be used to realize real-time adjustment of transformer output voltage through remote control, ensuring that the voltage at the grid connection point remains within the normal range.

(3) Operational Monitoring and Intelligent Regulation Strategies: Establishment of a Real-Time Monitoring System

A comprehensive real-time monitoring system should be established for the PV power station to monitor grid parameters such as voltage, current, power, and frequency in real time. Sensors installed at the grid connection point, inverter output end, and PV modules transmit collected data to the monitoring center in real time. Big data analytics and cloud computing platforms are used to analyze and process monitoring data, enabling timely detection of abnormalities such as voltage overvoltage.

For example, by setting an early warning threshold for voltage overvoltage, the system automatically sends an alert when the monitored grid voltage approaches or exceeds the threshold, reminding O&M personnel to take timely measures to prevent faults.

Regular Maintenance and Fault Troubleshooting

A strict regular maintenance plan should be formulated for the PV power station to conduct regular inspections, maintenance, and upkeep of equipment.

The operating status of equipment such as inverters, PV modules, cables, and transformers should be checked regularly to identify and repair potential fault risks in a timely manner. During maintenance, equipment parameters should be tested and recorded, and historical data should be compared to analyze equipment operating trends and predict potential faults in advance.