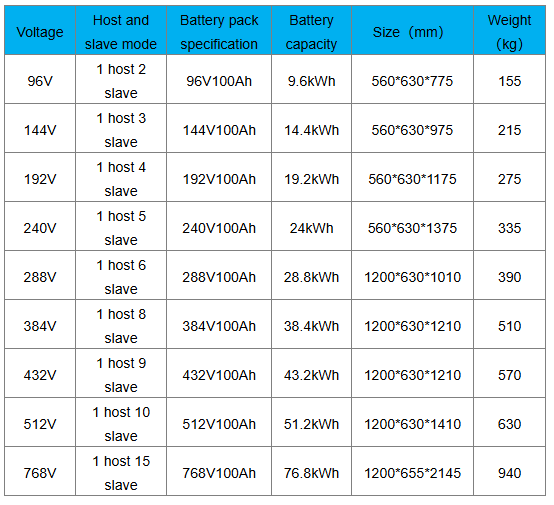

| Brand | POWERTECH |

| Model NO. | Combined type-high voltage energy storage battery |

| Mounting type | Stack mounting |

| Energy storage capacity | 28.8kWh |

| Master-slave mode | 1 host 6 slave |

| System architecture | Overall-Master-Slave |

| Series | Industrial&Commercial energy storage |

Combined type-high voltage energy storage battery free combination:

Technical parameter:

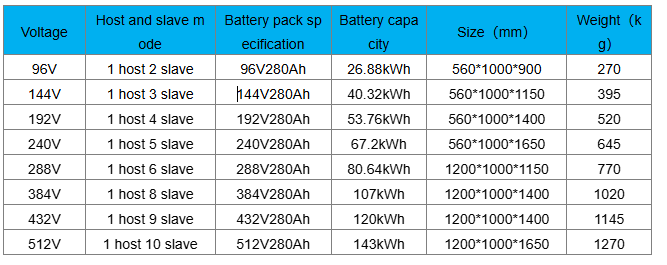

DCH series (Rack stack install)

DDH series(Cabinet drawer type install)

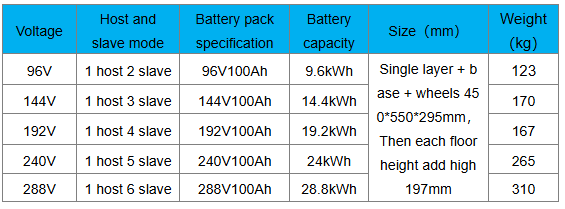

DSH series(gravity-stacked)

Unified parameter description:

Secondary architecture: The BMU and BCU control the data monitoring, charge and discharge, and energy management of the energy storage system.

Three-tier architecture: The BMU controller, BCU controller, and BAU controller are responsible for hierarchical management of modules and PACK clusters, and communication and control of air conditioners and fire fighting devices.

Fire protection: Cabinet type high pressure energy storage adopts a two-level fire protection scheme. A single battery contains 12g aerosol monomer automatic fire extinguishing device, and 300g aerosol monomer automatic fire extinguishing device in the cabinet.

Cell: Square aluminum shell lithium iron phosphate battery

Screen: High voltage system optional display: secondary structure add 500RMB, tertiary structure add 1800 RMB.

Life: 6000 cycles of product A standard DOD 80%/25℃/0.5C.

Communication mode: RS485/RS232/CAN Communication options: Bluetooth/WiFi.

What is High Voltage Direct Current (HVDC) technology?

High Voltage Direct Current (HVDC) technology is a technology used for long-distance power transmission. It is characterized by using direct current instead of traditional alternating current (AC).

Working principle.

Rectification:At the sending end, alternating current (AC) is converted into direct current (DC) through a rectifier.The rectifier is usually based on a thyristor rectifier or other solid-state switching devices such as IGBT (Insulated Gate Bipolar Transistor).

Transmission:The converted direct current is transmitted through high-voltage direct current cables or lines.

Since direct current does not generate inductive reactance and capacitive reactance, it has lower losses and is suitable for long-distance transmission.

Inversion:At the receiving end, direct current is converted back into alternating current (AC) through an inverter.

The inverter also uses thyristors or other solid-state switching devices.