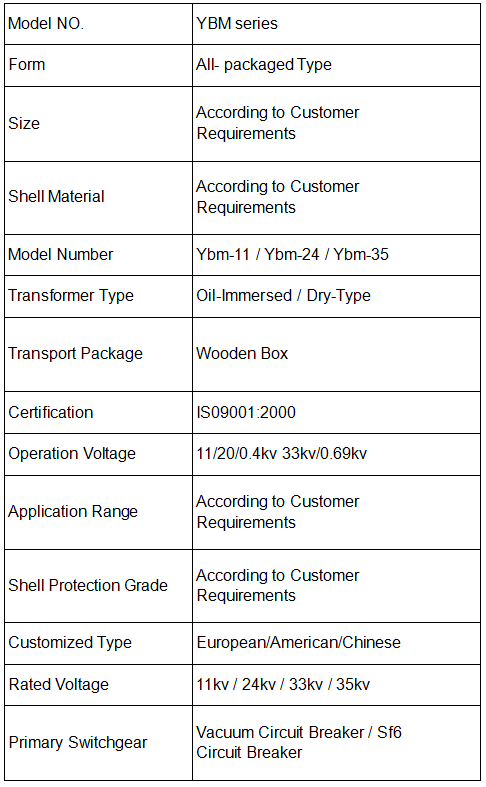

| Brand | ROCKWILL |

| Model NO. | 11kv Outdoor 35kv Prefabricated / Compact Substation Power Distribution Unit Box-Type Transformer Substation |

| Rated voltage | 11kV |

| Rated frequency | 50/60Hz |

| Series | YBM |

Descripton

The YBM22 series prefabricated substation represents an integrated power distribution solution. It ingeniously combines high - voltage electrical equipment, transformers, and low - voltage electrical equipment into a compact, modular unit. Tailored for diverse application scenarios, it proves ideal for urban high - rise buildings, urban and rural infrastructure projects, residential communities, high - tech development zones, small and medium - sized factories, mining operations, oilfields, as well as temporary construction sites. Serving as a dependable and efficient option, it facilitates the reception and distribution of electrical energy within power distribution systems.

Technical Parameters