Overview

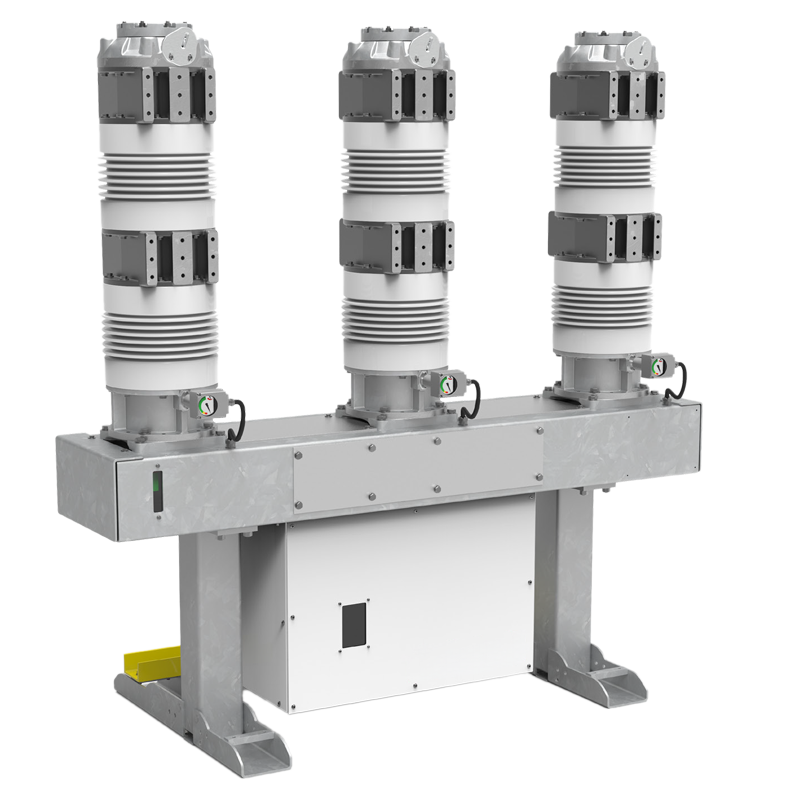

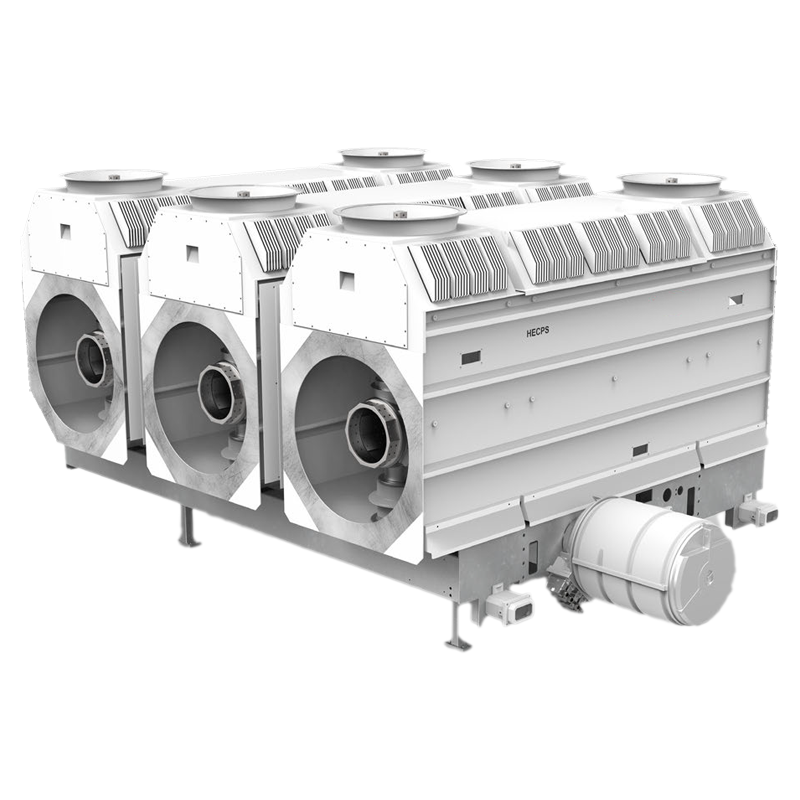

Innovative breaking chamber

The breaking chamber of HVS-63S is based on the highly reliable technology of open-type GCB HVR-63. The breaking chamber includes the double main contacts for double current commutation for higher stability of resistance to ensure the maintenance span of 20 years or 10,000 close-open operations. Featuring the advantage of a hydraulic spring operating mechanism, HMB-1, it uses 50 percent less energy compared to mid-sized GCBs for a more compact design and lower lifecycle costs.

Pressure relief device

Standard feature in the breaking chamber to improve safety and availability.

Erosion monitoring system

The breakthrough application of head-to-head contact system in HVS-63S enables an innovative built-in mechanical solution for a direct measurement and indication of arcing contact erosion. This real-time indication of the remaining time to service enables a timely planning of maintenance and increases the availability and reliability of the plant.

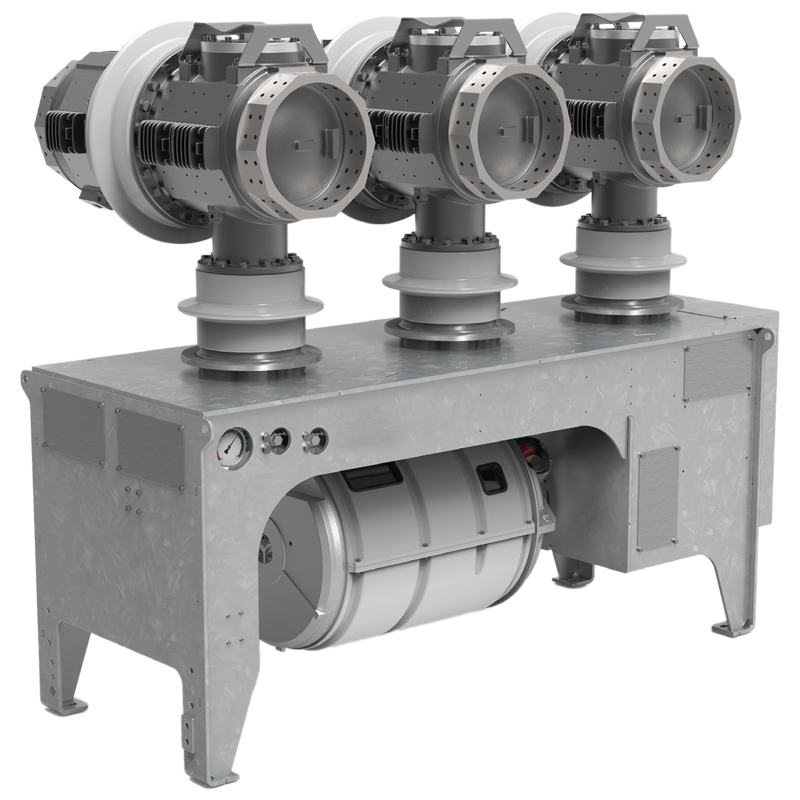

The most reliable spring drive HMB-1

CIGRE study (conducted in 2012) on high-voltage circuit breaker failures and defects in service revealed that the availability of the circuit breakers depends primarily on the reliability of the operating mechanism. These results from the study have endorsed the hydro mechanical spring drive as the most reliable operating mechanism for GCB applications. The hydraulic spring operating mechanism combines the advantages of a hydraulic operating mechanism with those of spring energy storage system with higher stability in the full range of the GCB operating temperatures and high consistency of timing during the entire lifespan for a safe performance.

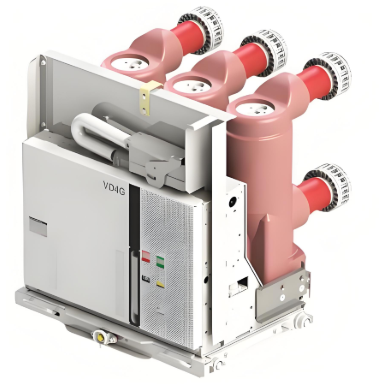

Combined disconnector-earthing switch and earthingswitch-starting switch

Combination of line disconnector with earthing switch andearthing switch with starting switch by three-positions disconnector allows the use of only one drive per disconnector for the lowest lifecycle cost, simplification of the switchgear and leaner management of the spare parts.

Low environmental impact

Only 5.1 kg of SF6 in three poles and a leakage rate lower than 0.1 percent per year. The advanced functions of GMS600 monitoring system, such as SF6 and temperature monitoring and trending (available on request), facilitates the control of such parameters.

Additional safety features

By using an advanced Geneva mechanism and key locks system, the design of the disconnector drives ensures full flexibility in implementation of the interlocking needs of the power plant. Special care in the encapsulation of the pole frame assures protection from unintentional access to moving parts between operating mechanism and switching components for the highest safety of operators & maintenance engineers. The breaking chamber technology from HVR-63 with very fast opening time assures the clearance of potential harmful faults in tens of milliseconds for higher protection of power plant assets.

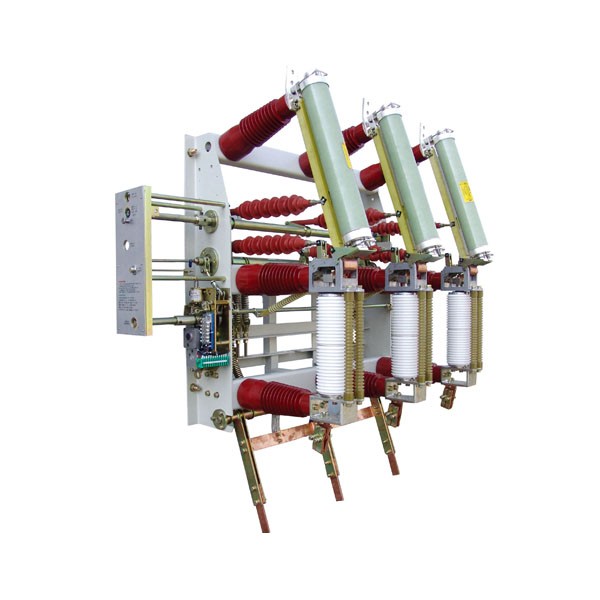

Type-tested according to latest standards

HVS-63S is type-tested according to the latest standards for GCB, including switching with full-phase opposition fault current (180° out-of-phase). Moreover, it is type-tested to interrupt current exhibiting delayed current zeros up to 130 percent degree of asymmetry, which are typical for turbo generators. The above capabilities exceed the mandatory requirements of the latest GCB standard and IEEE C37.013.

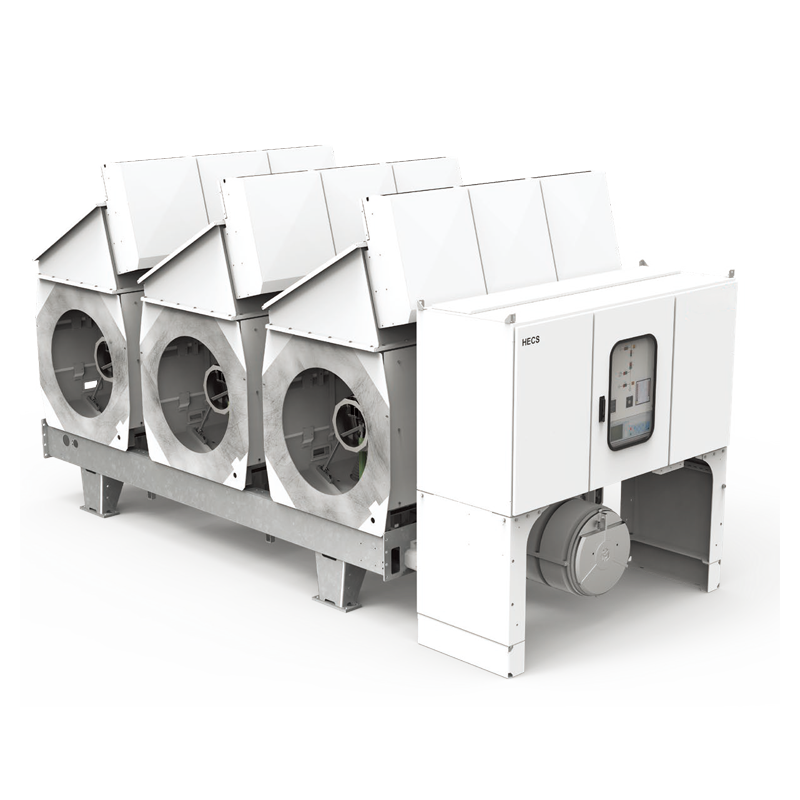

Compact design and easy handling

HVS-63S is fully assembled and tested at the factory for substantial cost and time saving in installation and commissioning process. Its compact design fits into standard 20-feet container for easy transportation, handling and storage. Combined with its plug-in system it leads to a simpler and quicker installation on-site.

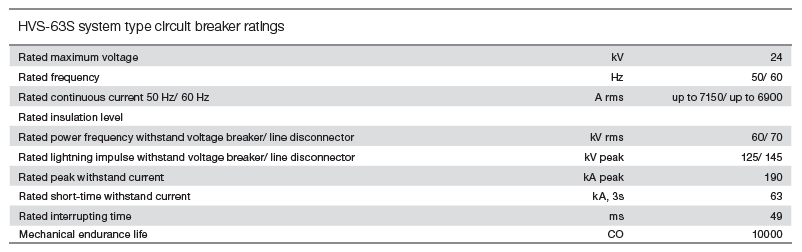

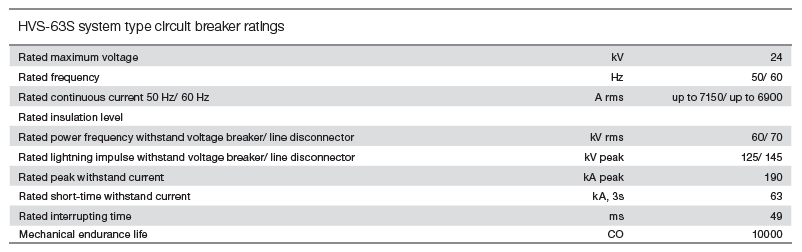

Technology parameters

Online store

On-time delivery rate

Response time

100.0%

≤4h

Company overview

Workplace: 108000m²m²

Total staff: 700+

Highest Annual Export(usD): 150000000

Workplace: 108000m²m²

Total staff: 700+

Highest Annual Export(usD): 150000000

Services

Business Type: Design/Manufacture/Sales

Main Categories: High Voltage Electrical Apparatus

Whole life care manager

Full lifecycle management services for equipment procurement, use, maintenance, and after-sales,

ensuring safe operation of electrical equipment, continuous control, and worry-free electricity

consumption.

The equipment supplier has passed platform qualification certification and technical evaluation,

ensuring compliance, professionalism, and reliability from the source.