| Brand | ROCKWILL |

| Model NO. | Low-Loss Three-Phase Photovoltaic Isolation Transformer |

| Rated frequency | 50/60Hz |

| Rated capacity | 1250kVA |

| Phases | Three-phase |

| Series | SGG |

Product Overview:

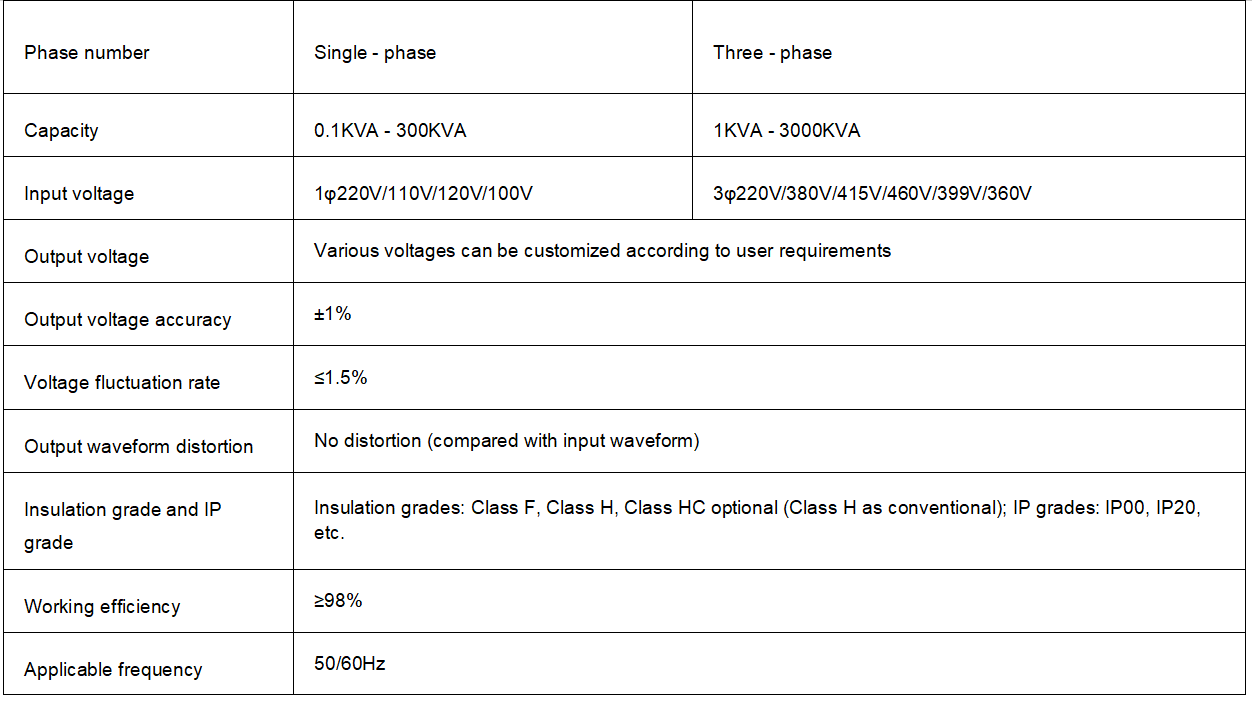

For many years, our company has specialized in manufacturing SD/SG(YSD) series single-phase and three-phase dry-type transformers dedicated to mechanical equipment, with capacities ranging from 1KVA to 3000KVA. Developed by referencing the latest similar products from Siemens, our SG series three-phase dry-type transformers not only provide voltage transformation in the power grid but also isolate third harmonics from the grid to equipment, reducing heat generation in machines and extending the service life of insulating materials. They are particularly suitable for imported equipment (380V input → 220V output, 380V input → any voltage output, 220V input → any voltage output) with specifications from 1KVA to 3000KVA.

Our SG and DG series dry-type isolation transformers are widely applicable to various power supply scenarios with AC 50-60HZ and input/output voltages not exceeding 3000V. All parameters, including input/output voltage levels, connection groups, tap positions, winding capacity distribution, secondary winding configurations, and whether a casing is required, are meticulously designed and manufactured according to user requirements.

Material Configuration Description of Transformer:

Transformers serve as the main components of various power supplies and electrical equipment. Isolation transformers consist of cylindrical windings and laminated cores, where the core is stacked with brand-new high-quality high-silicon silicon steel sheets using fully mitered joints. Our company employs advanced manufacturing processes, including imported Max high-speed automatic winding machines and a full set of vacuum pressure impregnation (VPI) equipment. The windings are formed using the skeletonless full-series winding method, and the transformers undergo vacuum impregnation to achieve insulation classes of F (155℃) or H (180℃).The input and output voltages of the transformer can be designed according to customer requirements, available in various specifications such as single-phase, three-phase, or multiple-way input/output configurations.

Core:Made of brand-new high-quality high-silicon silicon steel sheets, mainly with materials of 0.35mm thick H18, H14, H12, and Z11 high-quality silicon steel sheets. We select the most suitable material based on customer requirements and usage conditions to optimize the transformer's performance design. (Conventional material: brand-new high-quality silicon steel sheets).

Wire:Using PEW, UEW, EIW, SEIW, FEAI enameled wires and glass fiber-covered wires, with temperature resistance grades of F (155℃), H (180℃), HC (200℃), and C (220℃). (Conventional temperature resistance grade: H grade, 180℃).

Insulating Materials:Adopting high-temperature resistant insulating paper as the insulating material, which has multiple properties of high-temperature insulation, flame retardancy, and moisture resistance.

Insulating Material Terminal Blocks

Iron Feet:Mainly made of CNC bent cold-rolled steel plates, with environmentally friendly electroplating options such as multicolor plating (golden yellow), blue zinc (silver white), white zinc (ivory white), and surface anodizing (black).

Technical data:

Product Operating Conditions: